eBook

Unlocking innovation in Aerospace and Defense

Shorten aircraft design cycles with ESTECO’s digital engineering solutions for collaboration, simulation data management and multidisciplinary design optimization.

Webinar

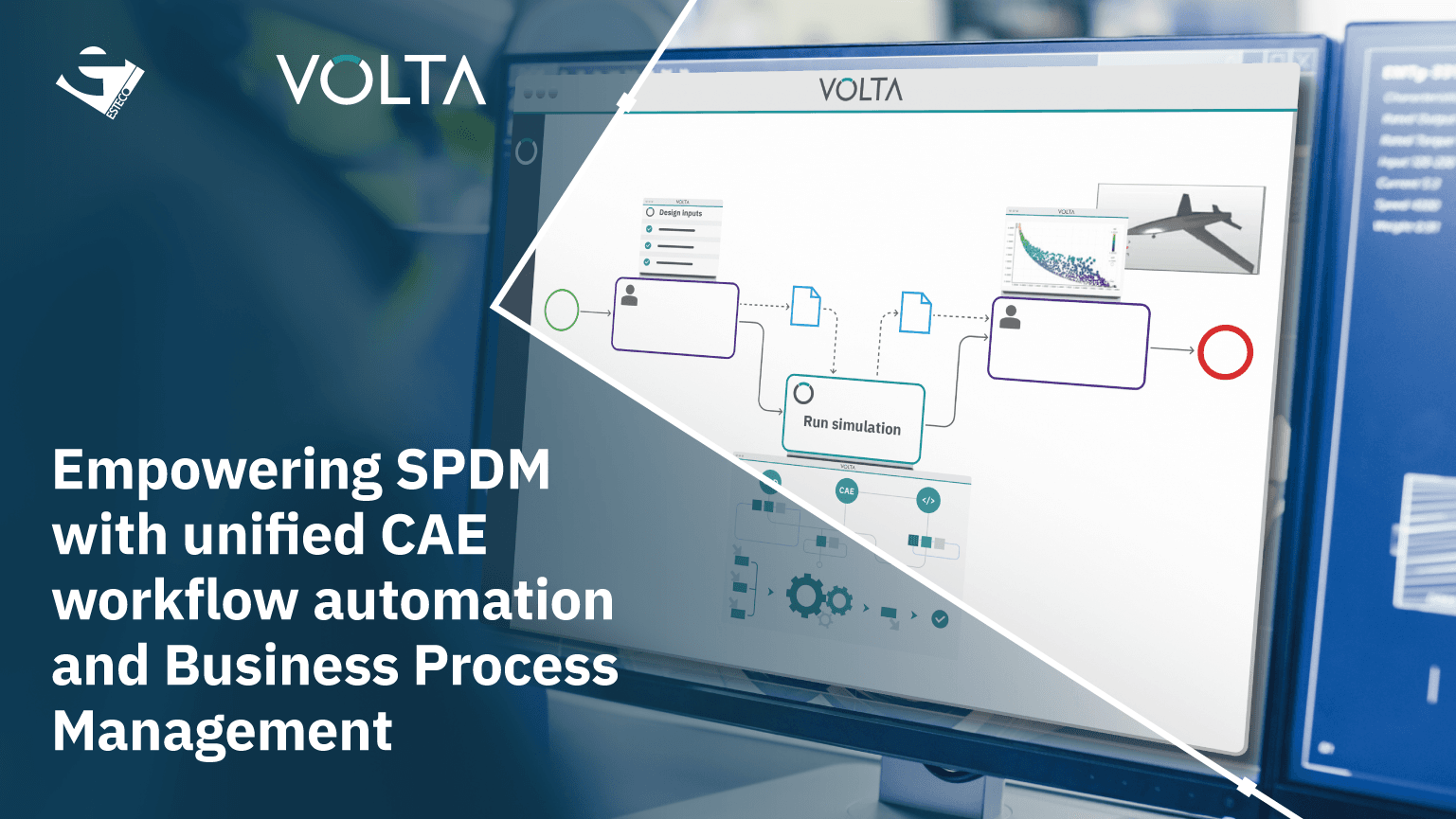

Empowering SPDM with unified CAE workflow automation and Business Process Management

Take a 30-minute deep dive into VOLTA BPM technology and learn how to automate human interactions and integrate simulation execution in a business process workflow.

All resources

Showing 51 - 60 of 126 resources

Webinar

Accelerate aircraft design with model-based design automation and collaborative MDO

This webinar hosted by ESTECO and TXT company PACE, demonstrates the added value of combining their technologies for a server-based optimization of an EXPEDITE (EXPanded MDO for Effectiveness Based DesIgn TEchnologies) derived preliminary aircraft design.

Taking an EXPEDITE-like modern aircraft conceptual design as a baseline, the webinar showcases the advantages of creating a smart, reconfigurable aircraft model with PACE's preliminary aircraft design platform Pacelab APD and integrating it in modeFRONTIER parametric optimization to identify the optimum solutions, based on constraints and performance requirements.

Watch this webinar and learn more about how to implement this methodology in an international context, consisting of distributed teams and the extended enterprise.

Webinar

Enhancing the design process in biomedical industry with engineering optimization

This webinar explores the possibilities of the use of modeFRONTIER and DEP MeshWorks to accelerate the design process in the biomedical field.

Medical devices community needs to adopt faster go-to-market strategies to go from conceptual design to market deployment. Virtual engineering and virtual testing become one of the key factors that enable this speed of development. Engineering simulation enables design, development, and analysis of these complex medical devices with great accuracy. Mathematical techniques such as numerical optimization and machine learning further enhance the design process by allowing the identification of robust and optimal solutions in a short time.

ESTECO North America and Detroit Engineered Products (DEP), specialized in model parameterization, explain the value of optimization and response surface modeling in simulation-based medical device development.

White paper

A new collaborative MDO strategy for improving vehicle design at Ford Motor Company

The role of innovation in the automotive industry has emerged as a key factor, with companies shifting their revenues from well-established models to new ones.

This white paper illustrates how Ford Motor Company achieved streamlined, multi-user design process management by expanding its Multidisciplinary Design Optimization (MDO) approach at enterprise level with the ESTECO technology.

Specifically, the deployment of the ESTECO platform for Simulation Process and Data Management (SPDM) made it possible for Ford engineers to:

process and generate large quantities of designs very quickly,

assure the immediate impact of results on vehicle design from the earliest design stages,

provide a wealth of data from which several useful design alternatives could be explored.

Video

ESTECO Technology: autonomous design space exploration

Whether you need to start understanding your engineering problem or you work under strict timelines, you can embrace our AI-based Autonomous Optimization approach and focus on the improvement you want to reach without any setting required.

Success story

Best performance of blast furnace with material charge optimization

Using modeFRONTIER coupled with Rocky DEM to design a better deflector while saving up to 130 hours of computational time

The Arvedi Group turned to the University of Trieste to find a solution to the uneven material distribution inside the hopper of the blast furnace in Trieste, Italy. The Mechanical Engineering Department investigated the problem and used modeFRONTIER to optimize the design of a new deflector ensuring a better distribution of the materials. Exploiting the ESTECO integration and process automation technology they coupled modeFRONTIER with Rocky DEM software to accelerate the simulation process of the material distribution. Using the proprietary algorithms available in modeFRONTIER, they were also able to find the optimal design for a new deflector. ## Challenge

The project concerned the charging process of coke coal and iron ore inside the hopper. The different materials formed piles and pitches, leading to a lower performance of the plant. The uneven material distribution inside the hopper caused variations in the temperature profile, gas flow, and gas composition. To solve this problem modeFRONTIER was coupled with Rocky DEM to get a better understanding of materials behavior and optimize the design of the deflector. The integration with modeFRONTIER also allowed to meet the time constraints, reducing the computational time for each simulation. ## Solution

This project was developed in two phases. The first phase concerned the calibration of Rocky DEM parameters and the simulation of hopper charge. The second phase consisted in optimizing the geometry of a new deflector for the charging process.For the calibration process, they used the parameters of Discrete Element Method as inputs in modeFRONTIER, such as particle- particle static friction and rolling resistance. The repose angle of simulated material was used as output. For the device optimization, a sensitivity analysis with Uniform Latin Hypercube allowed to run 90 designs and identify the most important design variables. Engineers then optimized three different geometries, taking these geometrical variables as inputs. The outputs were based on the material distribution, calculated by virtually splitting the hopper into 12 sectors and performing statistical analysis on the particles found in each. These values were used to define the two objectives and the constraints of the optimization. They used the ESTECO proprietary pilOPT algorithm to run the three optimization studies. Thanks to the autonomous mode they could evaluate more than 1000 designs in just a few weeks, without having to set any parameters and with remarkable benefits in terms of time.

Benefits

Thanks to a user-friendly graphical user interface, modeFRONTIER helped automate the simulation process. Without modeFRONTIER, engineers would have had to manually change the geometry of the deflector for every simulation, with significant waste of time. With modeFRONTIER they were able to save up to 130 hours of computational time. Finally, by automating the process, design engineers could launch the optimization and avoid the painstaking process of manually combining the output from multiple applications.

Video

modeFRONTIER Planner: the new optimization experience

Perfect your design by choosing among a complete set of intelligent algorithms. With the modeFRONTIER Planner modular environment you can create your DOE, RSM-based and optimization studies in an assisted way and focus on your engineering goal.

Success story

IVECO S-WAY truck: perfecting cab design to maximize driving comfort

IVECO relies on ESTECO technology to innovate its simulation-driven product development process. IVECO engineers combine the use of CAD and CAE solvers within modeFRONTIER workflow to automatically execute parametric simulations across a wide spectrum of disciplines: structural calculation (crash, durability, strength), fluid dynamics, NVH (Noise, Vibration, Harshness) and vehicle dynamics. On top of the automated simulation process, they apply optimization algorithms to achieve better vehicle designs with increased performance at reduced production costs. ## Challenge

The IVECO S-WAY is a complete transport solution which provides excellent life on board conditions to drivers. With a brand-new cab designed to enhance aerodynamic performance and increase fuel efficiency, engineers at IVECO had to completely rethink the suspension system to improve the comfort standard level. In fact, one of the main challenges of the project was to evaluate the cab comfort before the construction of any prototype. Consequently, they made use of multi-body simulation and optimization techniques to verify the overall behavior of the cab by defining the correct set of stiffness and damping parameters for the suspension elastic components.

Solution

A 3D truck model was generated in MSC Adams/Car to simulate the behavior of mechanical components (cab body, suspension, actuator, tractor and trailer frame) on different proving grounds as pave, patched asphalt and speed bump. The simulation model was directly integrated in modeFRONTIER workflow to automatically tune the suspension properties, with the aim of optimizing output parameters related to vibration, cab movements and comfort. An initial Design of Experiments (DOE) analysis allowed to identify the correlation between design variables and system responses, with the aim of simplifying the multi-body simulation model to be further validated in the optimization process. Finally, the MOGA-II algorithm, available in modeFRONTIER, enabled engineers to pick the right designs with minimized cab vibration on different paths.

Benefits

“We took advantage of modeFRONTIER software solution to automatically execute a huge number of simulations and evaluate thousands suspension system designs within few weeks. The Parallel Coordinate Chart enabled us to easily plot several variables and visualize the distribution of the designs in an effective manner. The optimization process led us to achieve up to 10% reduction in cab vibration compared to the baseline. Moreover, the results achieved with modeFRONTIER allowed us to identify specific properties of dampers, springs and bushes that have been considered during the prototype phase of the IVECO S-WAY truck development” said Andrea Morello, Performance Engineer and CAE Senior Analyst, IVECO - CNH Industrial.

Video

Turn data into valuable insights with VOLTA Advisor

Turn data into valuable insights with VOLTA Advisor. The advanced post-processing tool equipped with web-based interactive charts enables you to make informed decisions.

Handle thousand of data with a wide array of easy-to-use web-based analytics and visualization tools.

Filter out information and prepare reports with multiple interactive and synchronized dashboards.

Quickly compare the effectiveness of the optimization strategy and decide on design solutions.

White paper

Optimizing the Manufacturing Process to Make Robust Decisions and Reduce Uncertainty

In today’s Industry 4.0-driven market, companies strive to offer the most competitive and valuable solutions while being efficient and reducing costs. Unlocking the advantages of digital transformation is key to face these challenges.

Through production process optimization, manufacturers can improve their decision making process to enhance efficiency and quality, while reducing costs and uncertainty.

As a case study, this white paper illustrates how out ESTECO technology helped optimize a computer assembly line by:

increasing profitability, total throughput and same-day shipment,

minimizing work-in-progress, subject to a maximum allowed limit on staff utilization.

Webinar

Cloud-based optimization of mixer design for Urea/SCR aftertreatment systems

This webinar explains how modeFRONTIER was used to drive CONVERGE in the optimization of a Urea/SCR flapper-type mixer.

Meeting NOx (NO + NO2) emissions regulations with aftertreatment system designs that are both effective and economical is critical to successful product performance. The favored approach to satisfying NOx emissions regulations in heavy- and light-duty diesel vehicles is to use a Selective Catalytic Reduction (SCR) device where ammonia catalyzes to reduce NOx. Current industry trends are moving to more compact integrated Urea/SCR systems, which increases the need for an optimum mixer design that may be difficult to achieve with traditional design approaches.

ESTECO and Convergent Science during the webinar demonstrate how combining fast and accurate CFD simulation with effective multi-objective optimization of the geometry has the potential to substantially improve the mixer designs and produce high levels of NOx reduction without a substantial backpressure penalty.