Optimized Valvetrain System Boosts Two-wheeler Performance at Piaggio

- Company: Piaggio

- ESTECO Software Solution: modeFRONTIER

-

Benefits:Allow simultaneous modificationImprove stability and durabilityImprove the system in terms of kinematic and dynamic characteristics and thermodynamic performance requirements

Piaggio & C. s.p.a. uses modeFRONTIER optimization capabilities to improve a 125cc 4-valve engine design

The Piaggio Group is the largest European manufacturer of two-wheel motor vehicles and one of the world leaders in its sector. Headquartered in Italy and with Technology & Innovation centers located in India, China and Vietnam, Piaggio is known for its unique range of two-wheel and light transport powertrain vehicles. The company’s R&D activities focus mainly on reducing the environmental impact of its products and improving vehicle efficiency, performance and passenger safety. For many years now, Innovation & Research engineers have been using modeFRONTIER to achieve these design objectives.

"With modeFRONTIER we were able to avoid manual, time-consuming tasks and gain control of system behavior."

Challenge

Reducing the environmental impact of two-wheeler engines, in other words, increasing overall engine efficiency, means, amongst other things, opting for engine downspeeding or downsizing strategies, with the need of reducing engine friction; however, in order to maintain or improve vehicle performance, this requires an increase in specific engine power. The use of numerical models and calculation methodologies provide important support in pursuing these goals. In this case, the design of valve lift events and the valve train components are crucial when taking into account multiple engine issues like valve train systems stability, durability, resisting torque and engine breathing.

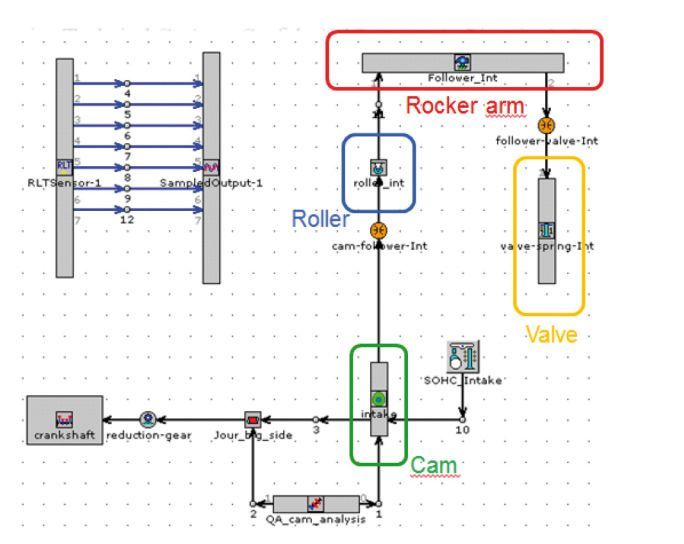

The GT® valve train model and valve train arrangement.

Solution

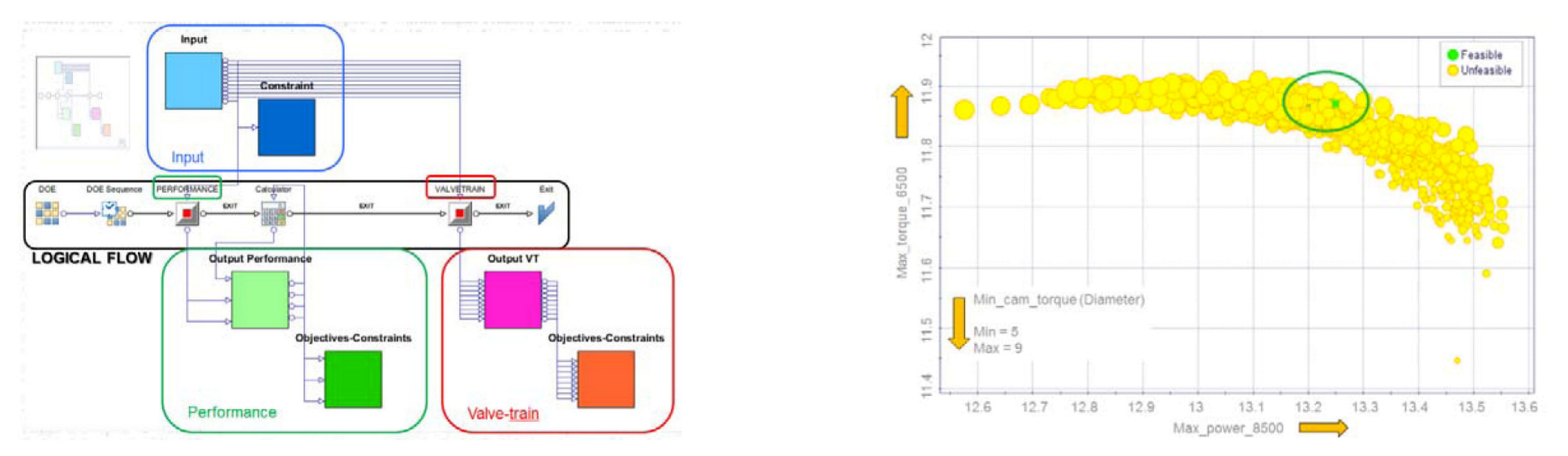

Starting with the baseline valve lift profiles of a 125cc 3-valve engine, engineers at Piaggio set up an automatic workflow within the modeFRONTIER environment that piloted the GT-SUITE calculation in order to evaluate the engine performance and the valve train system behavior in relation to specific valve lift profiles. “With this automated optimization approach we were able to avoid manual, time-consuming tasks involved in modifying the valve lift event in closed loop and to gain control of the entire system behavior”, says Francesco Maiani, Engine Calculation Engineer from Piaggio & C. s.p.a.

Benefits

“modeFRONTIER allowed us to adopt a modular approach to the problem that led us to the final valve lift event design. This methodology made it possible to define the valve lift event and support the analyst during the design of a cam profile. The optimization process sought to improve the system in terms of kinematic and dynamic characteristics and thermodynamic performance requirements”. This allowed engineers to simultaneously modify both the valve springs setup and the cam profile shapes, conveying the required response for the engine friction reduction. Additionally, the whole timing system benefitted from this procedure, also improving stability and durability.

The Piaggio Group is the largest European manufacturer of twowheel motor vehicles and one of the world leaders in its sector. The Group is also a major international player on the commercial vehicle market. The Piaggio product range includes scooters, motorcycles and mopeds from 50 to 1,400 cc marketed under the Piaggio, Vespa, Gilera, Aprilia, Moto Guzzi, Derbi and Scarabeo brands, including some of the most distinguished and historic names in the two-wheeler industry. www.piaggiogroup.com