Optimizing metal 3D printing process at Clemson University

- Institution: CEDAR Group at Clemson University

- ESTECO Software Solution: modeFRONTIER

-

Benefits:Save about three days of calculation time compared to the traditional optimization methodTailor the process parameters during the DMD manufacturing of functionally graded parts

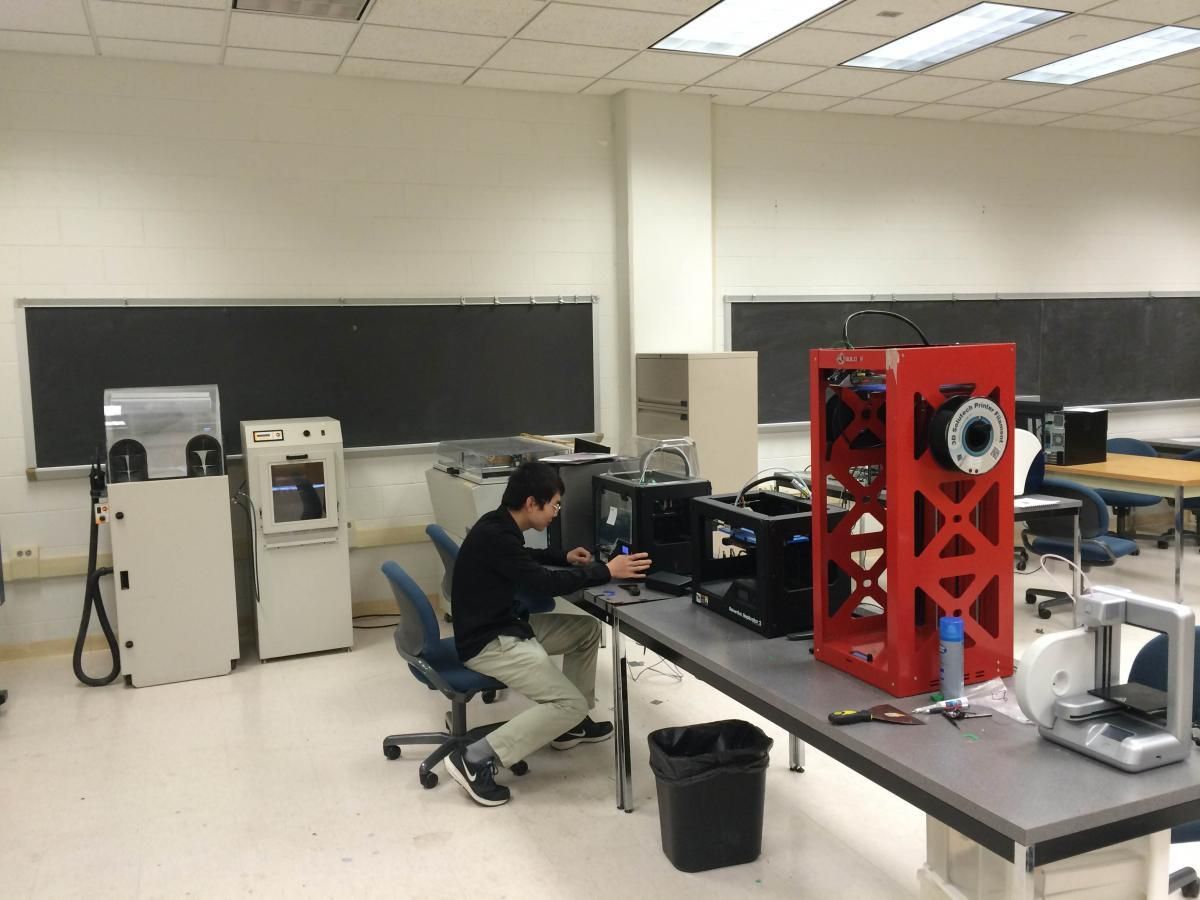

Jingyuan Yan, Ph.D in Department of Mechanical Engineering, used modeFRONTIER to develop his Ph.D research project focused on the design and optimization of the Direct Metal Deposition (DMD) process.

DMD is a 3D printing process for metal, similar to welding, using powders instead of wire. It uses a continuous wave or pulsed laser to induce a melt pool on a substrate, and metallic powders are delivered into the pool via injection nozzles. The process is able to deposit different metal powders onto different locations of the powder substrate in order to manufacture multi-material parts according to user requirements at the microscale level. Despite the benefits of DMD, this process is not widely used in industry: the building powder waste, the need for reduction of energy usage and inaccurate material composition in the fabricated parts are still critical issues. The DMD system provided by Optomec was used to implement the research.

"Using modeFRONTIER, we saved about three days of calculation time compared to the traditional optimization method."

During his research on DMD, Jingyuan worked on an injection nozzle designing first of all its geometry to maximize the process efficiency and investigate the relationship between the desired part’s composition and the process parameters. Jingyuan also wanted to improve the DMD process parameters considering their effect on efficiency when manufacturing multi-material parts. “In order to make the best use of powders and to minimize the laser energy consumption, we aimed at optimizing the process parameters. The bi-objective optimization problem was set up in modeFRONTIER workflow using the direct node to MATLAB. Eight design variables related to the process parameters (injection angles, velocities and nozzle diameters for the two materials as well as the laser power and the scanning speed) were set and automatically adjusted with modeFRONTIER to minimize the outputs results: powder waste and energy cost.".

“The multi-objective genetic algorithm (MOGA-II)” continues Jingyuan, “turned out effective in driving the search process and identify the designs which met the constraints on the deposition of multiple materials. As we see in the scattered chart, the feasible designs show a trade-off relationship between the two objective functions. The Pareto front results, marked with green color, enable the users to rapidly select the configuration with lower powder waste.” “The calculation process took about three hours. Using modeFRONTIER, we saved about three days of calculation time compared to the traditional optimization method. In the future, the optimization method can be applied to analyze other combinations of materials used in DMD, with any powder feed rate ratio. The results will be validated with experimental tests and it will be possible to generate a database of optimal process parameters for any given condition to be reused for future DMD projects. In the long run, modeFRONTIER can help tailor the process parameters during the DMD manufacturing of functionally graded parts, in order to get an accurate material composition as desired.”

The Clemson Engineering Design Applications and Research (CEDAR) Group at Clemson University is dedicated to exploring issues related to functional, usable and environmental design, with secondary emphasis on artistic design. They explore topics ranging from theories to tools, informatics to design education, creativity to decision making, function-based to affordance based, collaboration to representation, optimization to manufacturing, and packaging to complexity. They work with industry to help them innovate, improve their designs, and learn relevant approaches. Their group’s philosophy is to push the state of the art in design while graduating design practitioners, design researchers, and design tool developers. cecas.clemson.edu/cedar/