Luna Rossa Prada Pirelli: predict design performance with numerical optimization

- Company: Luna Rossa Prada Pirelli

- ESTECO Software Solution: modeFRONTIER

-

Benefits:Speed up simulation-driven design processExplore all the design space, finding unusual shapesQuickly and effectively obtain 2D section design and optimization for foils and rudders

Optimizing aero-hydrodynamics CFD simulations of AC75 yacht components with modeFRONTIER

Luna Rossa Prada Pirelli is all set to challenge for the Louis Vuitton 37th America’s Cup. Once again on an AC75 foiling monohull and representing the yacht club Circolo della Vela Sicilia for the third time. With the help of ESTECO simulation process automation and design optimization technology, the team has tested solutions and materials for their sailing yachts, built and developed in-house at the Cagliari base on Sardinia’s southern coast, Italy.

modeFRONTIER ticks all of the boxes: a flexible optimization tool that provides us with a wide range of state-of-the-art optimization algorithms, easy to use, allowing our engineers to be productive almost immediately. And, it’s a proven software product with a long record of successful usage.

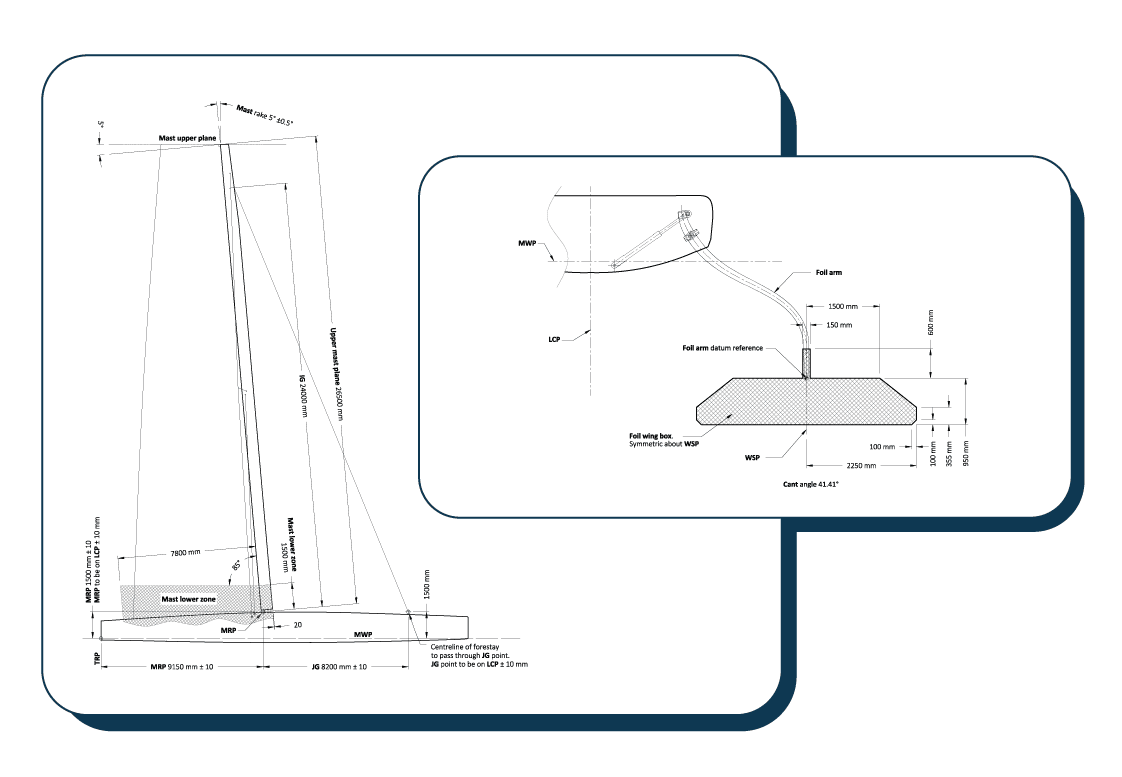

1. AC75 Class Rules: technical challenges

The AC75 Class has also been chosen to compete in the 37th America’s cup. It’s a high-performance monohull intended to spearhead the development of sailing through innovative technology, ensure the class is relevant to the sport of sailing and provide competitive racing in light and stronger wind conditions. The class rule defines the limits of the design space. Some parts, like the foil arm and foil cant system, are the same for every team. The AC37 Protocol also focuses on cost reduction, including limitations on the number of components:

- Teams are only permitted to build one new AC75

- Limitations on the quantity of foils and componentry that can be built for the AC75’s

- Introduction of the multipurpose One Design AC40 class which teams will be able to partially convert and use for testing, component development and Match Race training

- Possibility to use test boat (LEQ12) with max LOA 12m

Furthermore the towing tank or wind tunnel tests are prohibited. As a result, numerical simulation is a crucial and integral part of the design process at the Luna Rossa Prada Pirelli team. They analyze and optimize ideas before even seeing them applied to the yacht.

2. Design unit at Luna Rossa Prada Pirelli team

The 38-member unit forms the largest design team and is divided into five units: naval architecture, structural engineering, mechanical engineering, computer engineering, and aero-and hydrodynamic engineering. Among them, there is a group of designers who use modeFRONTIER to improve the design performance of AC75 yacht components:

- Matteo Ledri, Head of CFD

- Simone Bartesaghi, CFD Specialist

- Martin Jacoby, CFD Specialist

- Andrea Vergombello, Head of VPP

- Andrea Zugna, Performance & Mechatronics

In addition to designing hulls, sails, and custom components, the team analyzes data from simulators and computers connected to the boat during sea training. Through synchronized collaboration with the Sailing team and the Shore team, they work daily on studying and designing solutions to enhance the boat’s performance.

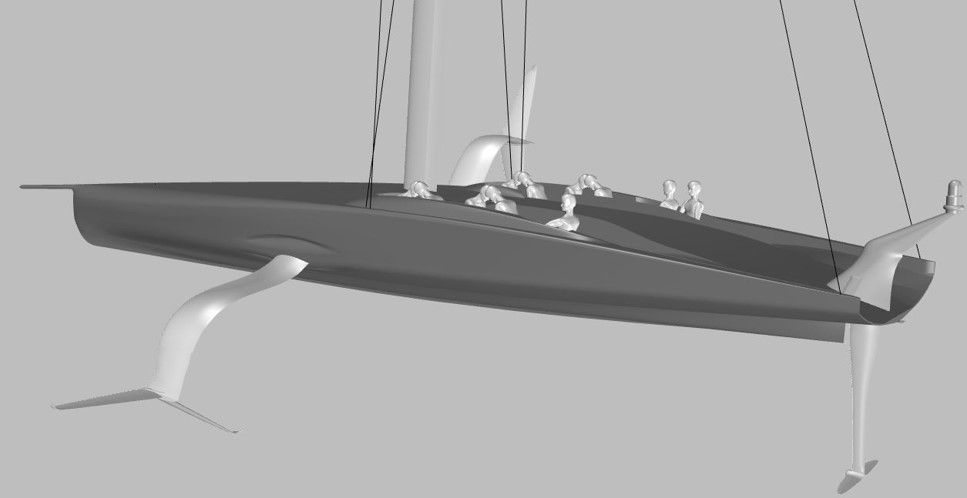

3. AC75 class yacht design: fly analogy

Foiling boats can be explained by comparing them to aircraft in case anyone has never seen one. These similarities can be useful to understand why simulation technology used in designing and testing foiling boats can draw upon decades of development in the aerospace industry. If you compare the AC75 boat to a glider, it is possible to identify the fuselage with the hull, the wing with the main wing foil, the winglet with the wing tip, and the rudder with elevator. The main difference in the case of the AC75 is that only one foil maintains the boat out of the water, so the roll balance is achieved by considering the upward force of the foil, the weight of the boat, and the roll component of the force of the sail, which is continuously adjusted to keep the boat upright.

Continuing the fly analogy, regarding controls, the pitch of the boat is controlled by the rake of the rudder blade, which changes the angle of attack of the rudder elevator. Ground clearance is maintained by controlling the flap angle of the foils.

4. Optimization technology to design yacht components more efficiently

The most precious commodity in an America’s Cup campaign is time, despite having a three/four year timeframe to design the yacht. This is why, when it comes to selecting tools for simulation, the design team prefers relying on proven and reliable commercial solutions. modeFRONTIER is one of those. The software offers flexibility, usability and straightforward methods for design exploration and optimization, making it possible to accomplish various automated tasks in a short amount of time. The optimization-driven design process begins with defining an objective function and constraints, followed by parameterizing the design, running an optimization algorithm, and validating the optimized solutions.

The model is from the 36th America’s Cup AC75 Version 1

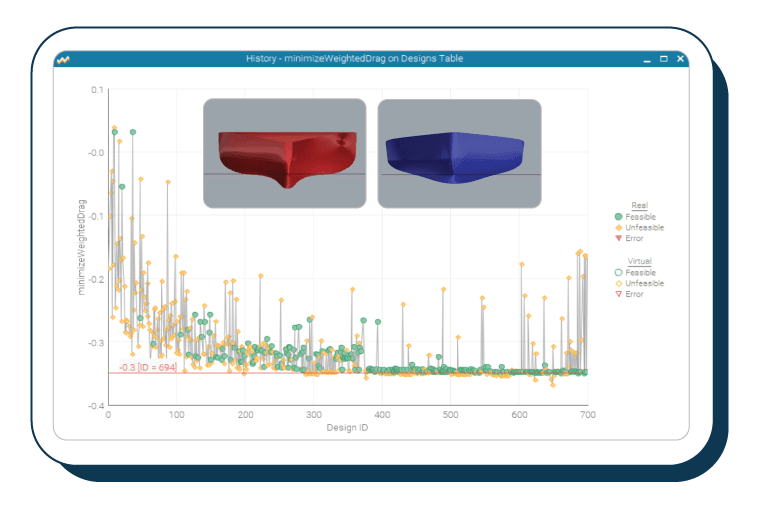

4.1 Hull shape optimization

For the hull shape, a preliminary investigation related to raw geometric parameters linked to the AC75 rules was done to try to cover the entire design space, even with out of the box shapes generated by using input parameters from a Design of Experiments (DOE) table.

Good candidates coming from a preliminary geometry optimization (rulewise) were tested via CFD hydro simulations and then the obtained data were integrated in modeFRONTIER to properly analyze the trends and compare the different solutions. By using the same approach, combining DOE exploration and direct optimization, the design space was refined in the optimum area extracted from preliminary design loops and updated at every step of the design itself.

modeFRONTIER design table: minimize weighted drag results

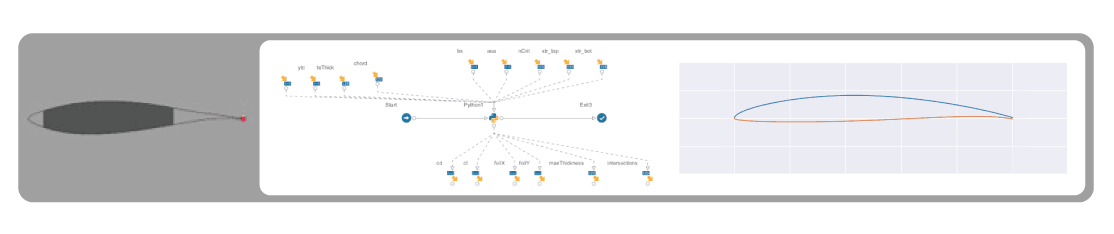

4.2 Optimization of the foil section

modeFRONTIER has been used extensively to perfect the design of the foil section by setting up a multi-objective optimization with genetic algorithms. The direct optimization allowed us to explore millions of possible shapes and select a family of best candidates to test and deep compare on the virtual AC75 complete model. The main goal was to minimize drag for a given lift with constraints like structural properties (stress and stiffness), cavitation, systems. Also, the process involved a parametrization based on B-Splines curves and parametric models to account for control system volume and some 3D effects.

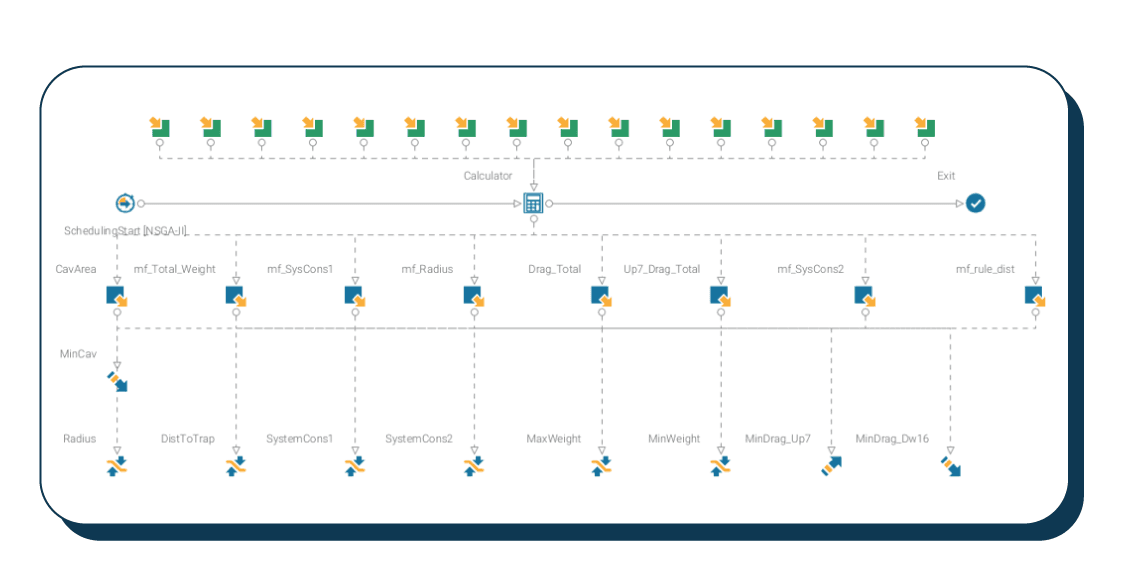

modeFRONTIER workflow for foil section optimization

4.3 Design space exploration of the wing

The design space of the wing was explored exhaustively using modeFRONTIER in two main areas: bulb and twist distribution.

This optimization task was very complex due to lots of constraints and objectives to be fulfilled. Regarding the bulb optimization, the requirement of a given volume to carry the required weight, the space to fit the flap system and a shape that has minimum as possible drag in all conditions. These are the constraints and objectives for the bulb optimization. The geometry generation was done with Rhino/Grasshopper and automated in modeFRONTIER to execute a DOE. Then, the geometry was sent to an HPC cluster to run a CFD analysis. In this context, modeFRONTIER enabled our team to efficiently perform this task and reduce the time to produce the optimized geometry. The purpose of Twist optimization was to find the optimum distribution of Angle of Attack of the hydrofoil section along the span of the foil.

This distribution of twist angle impacts several aspects of the foil performance and behavior. You could think about the structural part, where the center of lift spanwise will impact on the stress at the root of the wing, therefore asking for higher modulus which might lead to thicker sections. Seeking performance is the main objective where the aim is to fit the 2D section at a range of AoA where the efficiency is maximized, and from a 3D hydro point of view there is performance loss due to the eddies created by the lift produced. This with an optimal twist distribution can be minimized, always monitoring how the cavitation area gets modified with the twist changes.

modeFRONTIER workflow for bulb optimization

In that complex scenario modeFRONTIER fitting capabilities enabled us to find a virtual optimum with great confidence. The twist optimization problem had big non-linearities related to the laminar-turbulent transition and with the correct settings we were able to optimize with Response Surface models (RSM) techniques and validate the optimum with excellent results.

4.4 RSM modeling for wave model fitting: hydro and aero

Lots of challenges require CFD computations that are very costly in terms of computational power, however with the correct study of the problem, a good fitting of the CFD response can be done and then being used to reduce the need of simulations to be run. The choice of the RSM settings is of major importance, not only should be checked with validation points but also with engineer’s criteria. Later the fitting can be used to “anchor” low fidelity models that can expand the scenarios studied. Anchoring means that the expected difference between the high fidelity and the low fidelity model is studied and fitted and when that is known, it can be used to correct the low fidelity model in other parts of the design space, where a specific high fidelity simulation has not been run. Here the cases of study are the wave-resistance model of the AC75, where the URANS have been conducted at “center” sailing conditions. And, with the creation of an analytical wave model it was possible to expand the results to a very big amount of conditions that a wave scenario can have, think about wave height, wave period, angle, flight height.

modeFRONTIER was used to bring up the quality of the low-fidelity model and enable us to study a broader space.

5. The value of ESTECO Technology for Luna Rossa CFD specialists

modeFRONTIER has become an indispensable tool in developing the new AC75 class boat, providing the design team with the necessary optimization techniques to excel in various fields such as hull and foil design. Simone Bartesaghi, CFD Specialist, Luna Rossa Prada Pirelli says, “modeFRONTIER has helped us to improve and speed up our design process, allowing us to explore all the design space and finding unusual, out of the box shapes that we may not have considered otherwise. Based on our results from modeFRONTIER, we could quickly and effectively obtain 2D section design and optimization for foils and rudders, and even adapt them for different zones along the span of a foil or rudder. Finally, the software enabled us to create models for complex scenarios like waves interaction and aerodynamics forces for direct optimization".

The Luna Rossa team was born in 1997 when Argentine yacht designer German Frers proposed to entrepreneur Patrizio Bertelli to challenge for the 30th America’s Cup to be held in New Zealand in 2000. Since then, the team has taken part in five editions of the America’s Cup, winning the Challenger selection regattas twice - the Louis Vuitton Cup in 2000 and the PRADA Cup in 2021 - and competing in the final in 2007 and 2013. In the 36th America’s Cup presented by PRADA final match against the Defender Emirates Team New Zealand, Luna Rossa Prada Pirelli achieved the best score ever by an Italian challenger in the history of the America’s Cup. Luna Rossa will represent the yacht club Circolo della Vela Sicilia once again in its challenge for the 37th edition of America’s Cup to be held in Barcelona, Spain in September and October 2024.