Lucid Motors boosts electric vehicle performance with modeFRONTIER

- Company: Lucid Motors

- ESTECO Software Solution: modeFRONTIER

-

Benefits:Identify inverter optimal designs while enhancing efficiency and minimizing failure ratesMake more power available to the inverter and increase alternative current from 1200 to 1500AOptimize suspension components and enhancing the thermal performance for the motor cooling

"modeFRONTIER helped optimize temperature and pressure for our new generation electric vehicle inverter."

Performing multi-objective inverter cooling system optimization with modeFRONTIER

California-based electric car company, Lucid Motors, applies innovative engineering, design and technology to define a new class of premium electric vehicle. Their first Lucid Air all-electric sedan, with up to 400 mile range battery options and 1,000 horsepower twin-motor configuration with all-wheel drive, is to be delivered in 2019. In preparation for production, Lucid Air prototypes are undergoing a rigorous development program. modeFRONTIER has been used - together with other applications - to optimize the design of an inverter with the aim of enhancing efficiency and minimize failure rates.

Challenge

An inverter is an electronic device that converts the direct current (DC) stored in the battery into alternating current (AC) and send electricity to the three phases of the AC induction motors. Overheating is the most critical issue beside vibration, humidity and dust when designing a drive inverter for hybrid and pure electric vehicles. Its efficiency is instead driven by low chipto-coolant thermal conductivity together with temperature balance and low pumping pressure. The Lucid Motors team focused on designing an inverter cooling system that keeps the temperature under control.

Solution

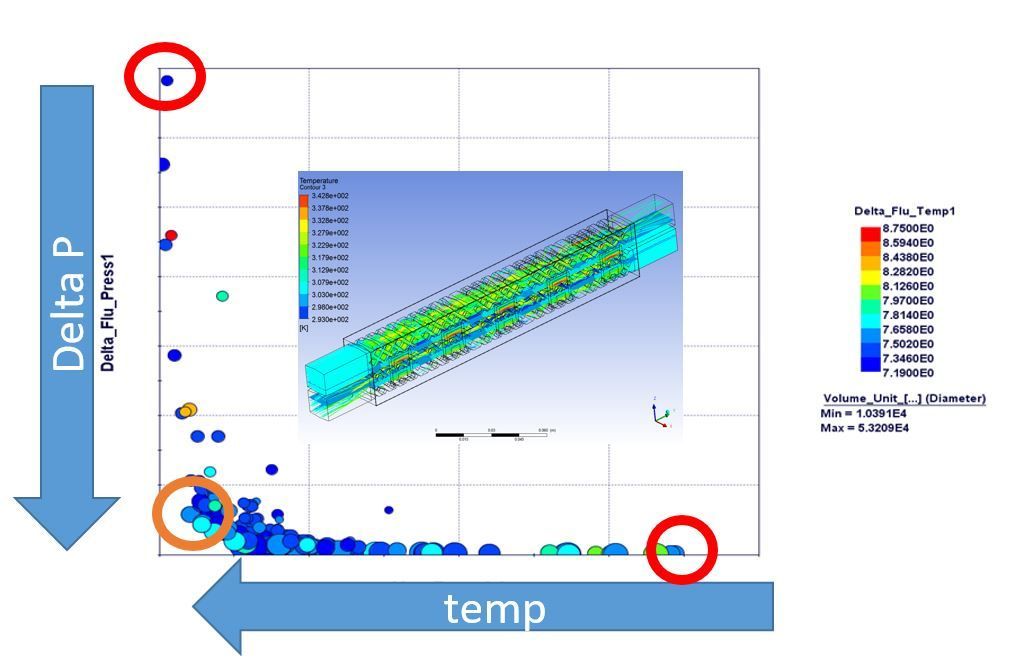

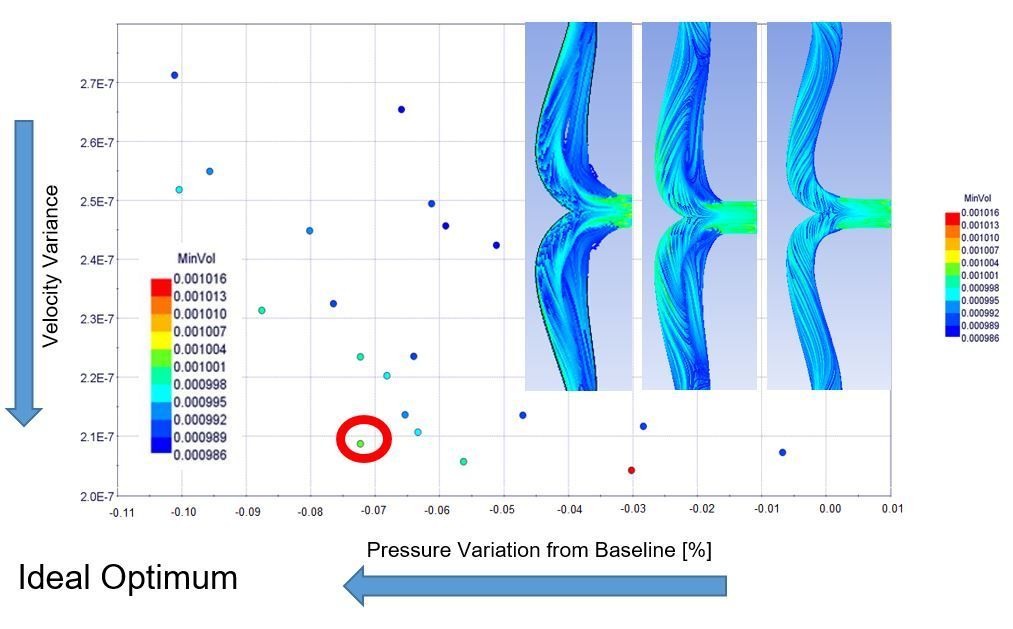

Starting from the conceptual design of a cooling channel with different configurations, engineers at Lucid Motors performed different Design of Experiments (DOE) evaluations and sensitivity analysis using a fully-parametric CFD model with modeFRONTIER, which enabled them to find optimal design candidates for temperature reduction, lowering pressure and minimizing channel size. “After deciding on an optimum channel solution, we went further and optimized the manifold design by including a mesh-morphing step in the modeFRONTIER process integration workflow. The objectives there were to keep pressure variations low and reduce velocity variation”, said David Moseley, Director, Powertrain, Lucid Motors.

Benefits

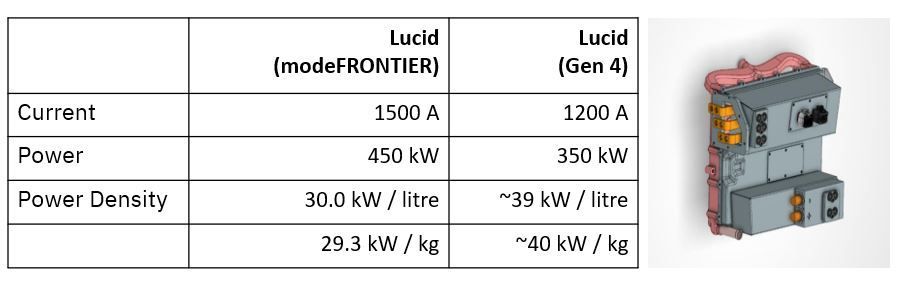

modeFRONTIER provided an environment to identify inverter optimal designs while enhancing efficiency and minimizing failure rates. The use of modeFRONTIER enabled Lucid engineers to make more power available to the inverter and increase alternative current from 1200 to 1500A. The ESTECO Technology also supported the Lucid Air development in optimizing suspension components and enhancing the thermal performance for the motor cooling.

Optimized manifold design with lower pressure variations and reduced velocity variation.

Lucid Motors is a premium mobility company that is reimagining what a car can be. The company is applying innovative engineering, design, and

technology to define a new class of premium electric vehicle. Headquartered in Menlo Park, California, in the heart of Silicon Valley, the Lucid

Team brings deep expertise from the automotive and technology industries. The Lucid Air all-electric sedan combines forward-looking design with

groundbraking technology to establish an entirely new class of vehicle. lucidmotors.com