Best performance of blast furnace with material charge optimization

- Company: Acciaierie Arvedi

- ESTECO Software Solution: modeFRONTIER

-

Benefits:Evaluate 1000 designs in just a few weeksAvoid the process of manually combining the output from multiple applicationsSave up to 130 hours of computational time.

Using modeFRONTIER coupled with Rocky DEM to design a better deflector while saving up to 130 hours of computational time

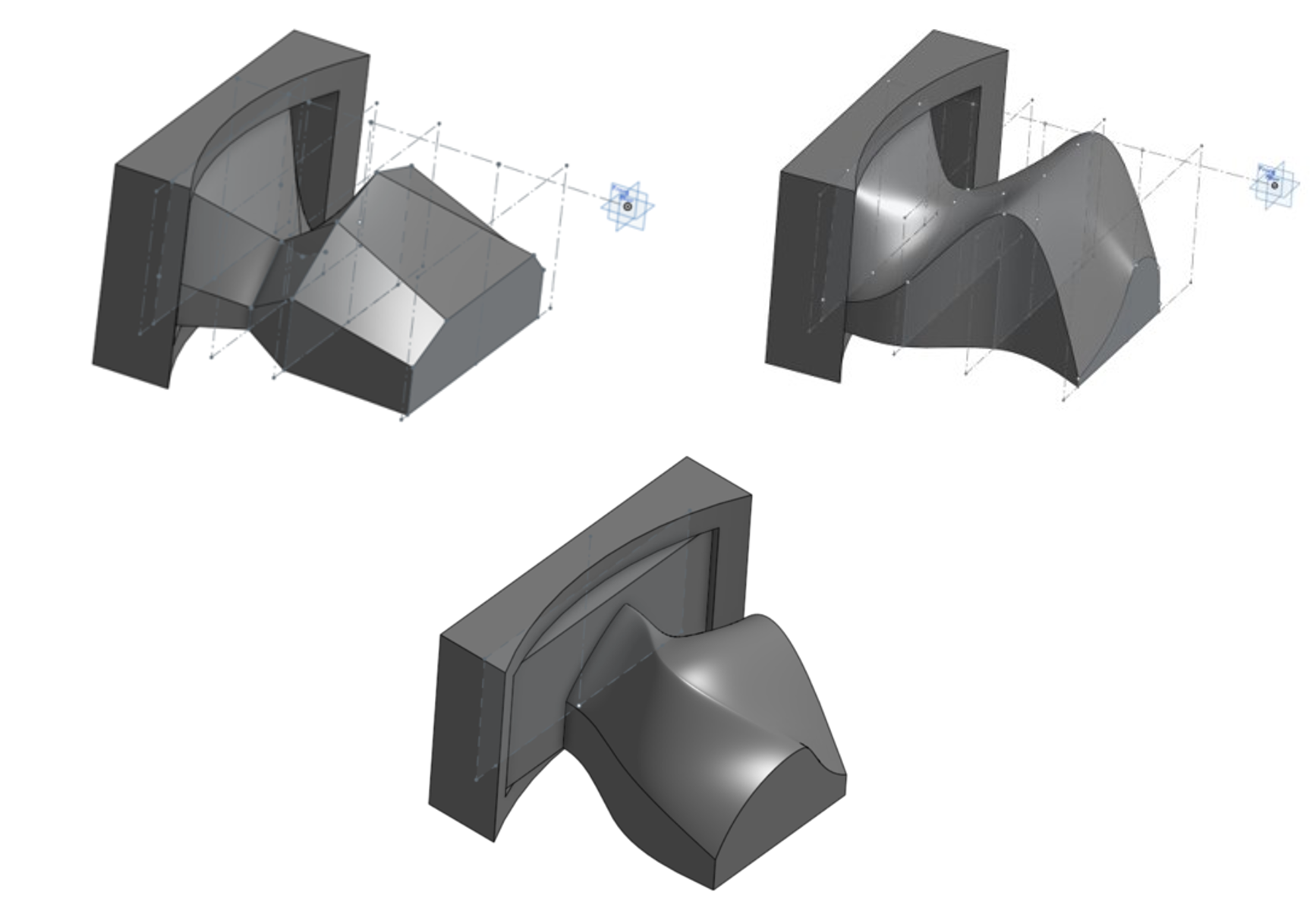

The Arvedi Group turned to the University of Trieste to find a solution to the uneven material distribution inside the hopper of the blast furnace in Trieste, Italy. The Mechanical Engineering Department investigated the problem and used modeFRONTIER to optimize the design of a new deflector ensuring a better distribution of the materials. Exploiting the ESTECO integration and process automation technology they coupled modeFRONTIER with Rocky DEM software to accelerate the simulation process of the material distribution. Using the proprietary algorithms available in modeFRONTIER, they were also able to find the optimal design for a new deflector.

"With modeFRONTIER, we could evaluate 1000 designs in just a few weeks."

Challenge

The project concerned the charging process of coke coal and iron ore inside the hopper. The different materials formed piles and pitches, leading to a lower performance of the plant. The uneven material distribution inside the hopper caused variations in the temperature profile, gas flow, and gas composition. To solve this problem modeFRONTIER was coupled with Rocky DEM to get a better understanding of materials behavior and optimize the design of the deflector. The integration with modeFRONTIER also allowed to meet the time constraints, reducing the computational time for each simulation.

Solution

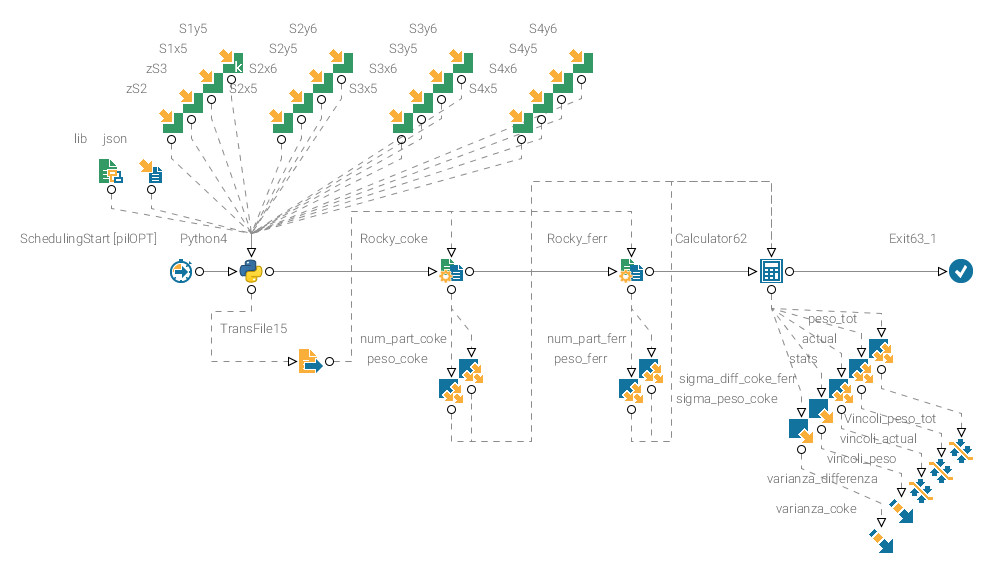

This project was developed in two phases. The first phase concerned the calibration of Rocky DEM parameters and the simulation of hopper charge. The second phase consisted in optimizing the geometry of a new deflector for the charging process.For the calibration process, they used the parameters of Discrete Element Method as inputs in modeFRONTIER, such as particle- particle static friction and rolling resistance. The repose angle of simulated material was used as output. For the device optimization, a sensitivity analysis with Uniform Latin Hypercube allowed to run 90 designs and identify the most important design variables. Engineers then optimized three different geometries, taking these geometrical variables as inputs. The outputs were based on the material distribution, calculated by virtually splitting the hopper into 12 sectors and performing statistical analysis on the particles found in each. These values were used to define the two objectives and the constraints of the optimization. They used the ESTECO proprietary pilOPT algorithm to run the three optimization studies. Thanks to the autonomous mode they could evaluate more than 1000 designs in just a few weeks, without having to set any parameters and with remarkable benefits in terms of time.

Benefits

Thanks to a user-friendly graphical user interface, modeFRONTIER helped automate the simulation process. Without modeFRONTIER, engineers would have had to manually change the geometry of the deflector for every simulation, with significant waste of time. With modeFRONTIER they were able to save up to 130 hours of computational time. Finally, by automating the process, design engineers could launch the optimization and avoid the painstaking process of manually combining the output from multiple applications.

Founded in 1963, the Arvedi Group is one of Europe’s most significant steelmaking realities, operating in the production of hot-rolled pickled, galvanized and pre-painted coils, carbon and stainless steel tubes and stainless steel precision-rolled strip. arvedi.it