SPDM and 3D CAE visualization: communicate design insights more effectively across your organization

Written by Marco Turchetto and Andres Rodriguez-Villa

20 July 2023 · 10 min read

In today’s world, there is a general pressure to improve product performance, compress design cycles, lower weights and reduce costs. As a result, it is becoming more important than ever to have a clear and accurate understanding of the product and systems being designed. With virtual models replacing physical testing, relying solely on static 2D charts and images is no longer sufficient. These visualizations offer a limited view. They only provide data for a single point of view and do not allow for interaction with the simulation results.

To make informed decisions, you need to examine simulation data in a way that closely matches the real-world experience. This is where 3D computer-aided engineering (CAE) visualization comes in. By inspecting and interacting with 3D models from all angles and in real-time, you can identify potential issues and make necessary adjustments before the product is manufactured, which can ultimately save time and money.

There are a lot of CAE visualization tools available in the market, but most of them just provide the results for the surface of the model. If you want to perform a more in-depth analysis, like identifying the location of maximum stresses and deformation or analyzing how the flow field develops in all areas of the model, the solutions out there don’t necessarily provide you with any access to the information inside the model itself.

Even if you use a reliable 3D CAE visualization toolkit, this may not be enough alone when multiple stakeholders are involved in the simulation-driven design process. There is a need to add a digital engineering framework for Simulation Process and Data Management (SPDM) where a wider audience of engineers can share 3D CAE results in a clear way and get useful insights for informed decision making.

Why CEETRON Envision for CAE data analysis and visualization

Making complex CAE data accessible to a wider audience in an SPDM environment is a serious challenge for anyone. First, there needs to be a high-fidelity representation of real 3D parts and systems that are being designed and simulated (enough of tables and images!). Furthermore, within a web-based collaborative environment, the question of security is always top-ranked among the concerns of SPDM developers. Finally, and most urgently, the user experience with respect to 3D model interaction needs to be flawless in terms of fluidity and visual quality.

While reinventing the wheel can feel rewarding if you don’t know it exists and until you realize it does, in most mature industries products are built by aggregating components to a high value core specific know-how which is the making of an organization’s value. This is not only what big engineering industries such as automotive, aeronautics and energy tell us, but also (all?) other fields such as pharmacy, food industry and others. Decomposing a product and relying on specialists for each component is at the end of the day the only rational choice when the start-up dust has settled on a market.

Our “niche” CAE playground is no exception. After the gold-rush years (late 80s, 90s), followed by the consolidation ones (2000s, 2010s) we are now securely in an aggregation and rationalization mode. This is today the context where component-based development becomes appealing to CAE developers such as SPDM providers. Tech Soft 3D has a 25+ year history of fueling components to innovative 3D engineering applications and has accompanied the growth and maturing of the market. In the CAE space, the CEETRON component product line is a major player in areas such as interoperability, meshing, solving, data extraction and visualization.

The CEETRON Envision toolkit that now powers the CAE analysis and visualization in VOLTA, ESTECO’s high-end SPDM system, ticks all boxes.

The CEETRON Envision toolkit that now powers the CAE analysis and visualization in VOLTA, ESTECO’s high-end SPDM system, ticks all boxes: its WebGL client-side rendering ensures optimal security, a desktop-like user experience while drastically cutting costs as servers do not need GPUs. While providing an efficient remote rendering solution, CEETRON Envision also accelerates development by offering off-the-shelf optimized data extraction algorithms to produce popular CAE post processing artifacts such as cutting planes, animations, plots, isosurfaces, etc…

CEETRON Envision for CAE data analysis and visualization.

ESTECO VOLTA SPDM platform delivers a collaborative web post-processing experience with embedded 3D CAE visualization

When using ESTECO VOLTA, the digital engineering platform for SPDM and Design Optimization, you can make better design decisions faster by using its 3D CAE web visualization (powered by CEETRON Envision).

Let’s assume that a team of engineers is tasked to predict the design behavior of a front lower control arm. The goal is to improve vehicle’s stability and handling performance. Therefore, the design process involves a series of tasks: defining a new geometry, performing a dynamic analysis of the whole suspension, running the structural and modal simulation of the component.

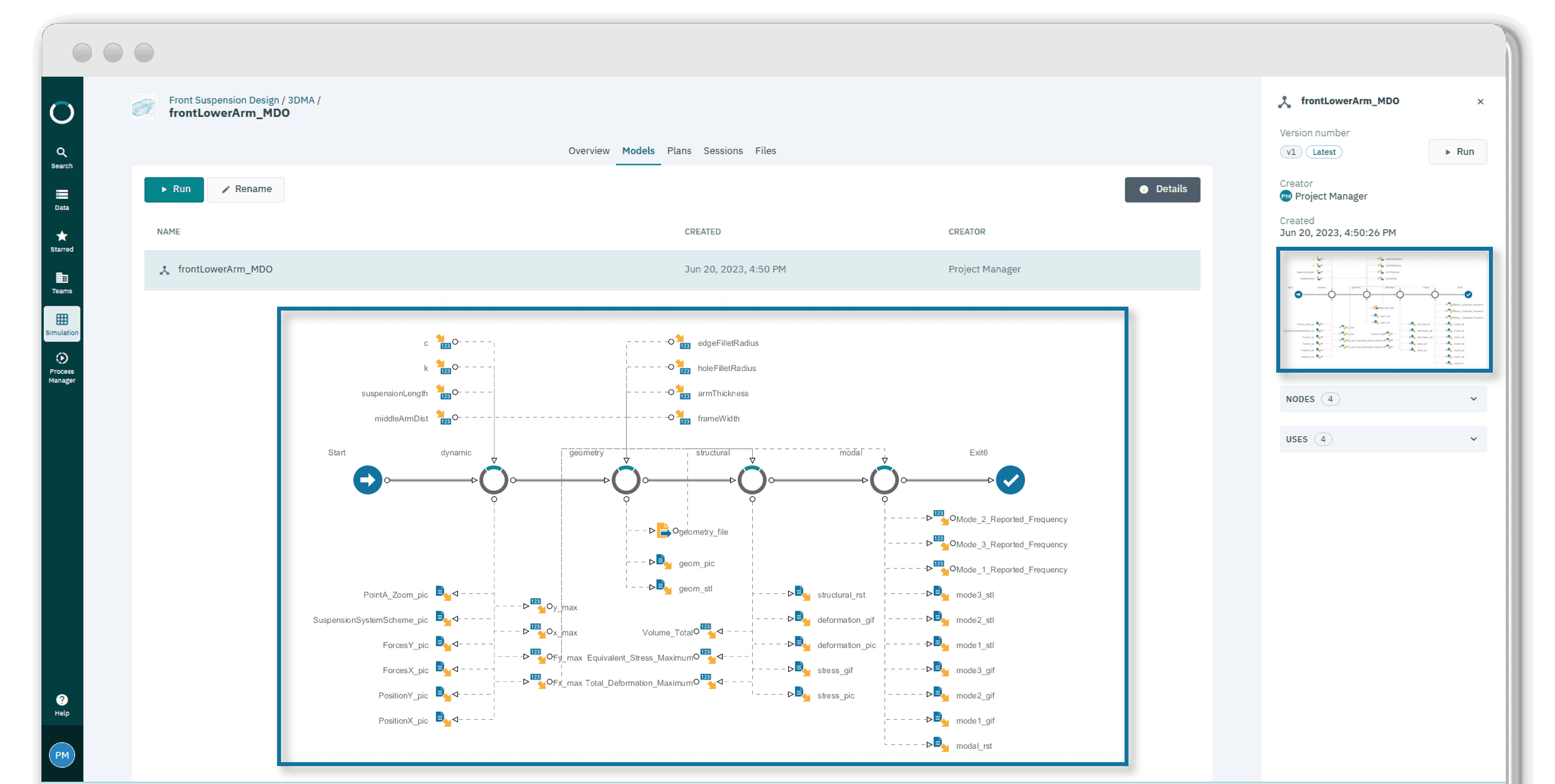

When it comes to dealing with a challenge such as that, the VOLTA platform can be of great help. Its web-based data management repository allows experts from different engineering fields to store and share their CAD geometry, dynamics, structural and modal analysis models. However, this is just the beginning of the simulation-driven design journey. Then, a method developer can concatenate and actionate all of these models into the ESTECO’s modeFRONTIER simulation workflow. In fact, this project requires multidisciplinary analysis to assess the suspension arm performance from various disciplines’ perspectives. There are interconnections between dynamics, structural, and modal disciplines, with shared inputs and outputs affecting one another.

Once the simulation workflow is ready, it can be seamlessly used by other team members to execute multidisciplinary analysis via web from VOLTA.

VOLTA leverages modeFRONTIER technology to build, publish and execute simulation workflows via web.

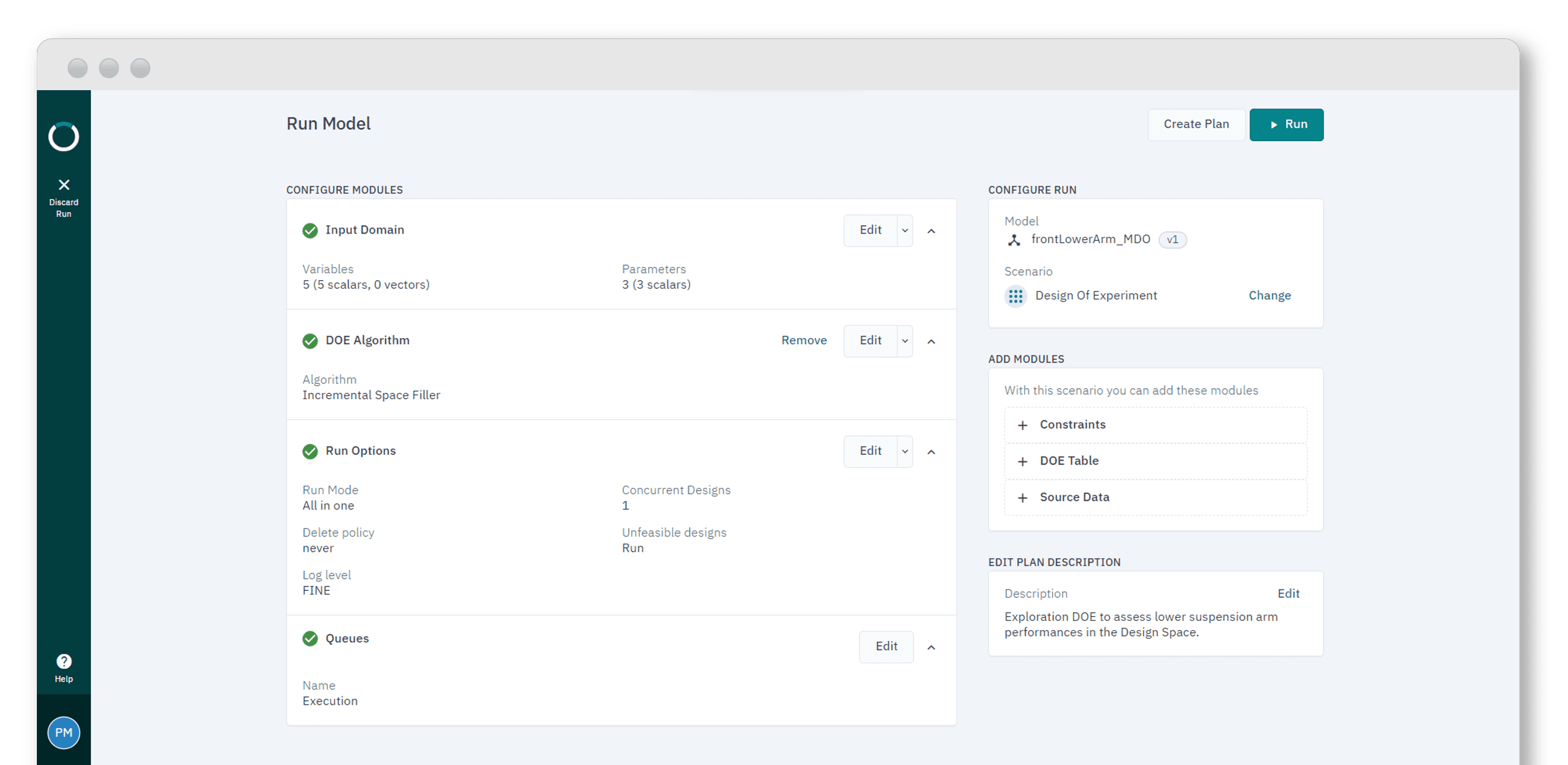

The next step is to extend the CAE toolchain automated in the simulation workflow to Design of Experiments (DOE). From the VOLTA Planner interface, a subject matter expert can easily set up and verify the behavior of a suspension arm in the design space based on many different combinations of input parameters.

With VOLTA Planner, any subject matter expert can apply design space exploration studies on top of the automated simulation workflow stored in the VOLTA SPDM platform.

After the DOE evaluation, the goal is to choose the most promising front lower control arm designs. As a result, these data are used in the next optimization strategy in order to achieve the best configuration of the control arm, which meets the requirements and maximizes performance. After the optimization run, VOLTA Advisor web-based post-processing tools come into play to extract meaningful insights from the generated optimization results.

VOLTA Advisor provides CAE analysts with web-based post-processing dashboards enriched with 3D CAE visualization (powered by CEETRON Envision).

Through VOLTA Advisor, CAE analysts can create their own custom post-processing dashboards for analyzing the optimization results. Among the multitude of widgets available in VOLTA, these are essential to measure the performance metrics of the suspension lower control arm in order to make informed decisions.

- Scatter bubble chart: to explore the performances of the designs that lay on the Pareto frontier

- Parallel Coordinates chart: to get an overall view of all different configurations for all performance metrics

- 2D image: to look at a specific design's simulation results

- 3D Model Analyzer (powered by CEETRON Envision): to perform a quick initial post-processing of the original CAE model by creating section planes and analyzing the stresses inside the control arm.

We wanted to add CEETRON Envision technology within our VOLTA SPDM platform to allow our users to perform a more in-depth analysis of the CAE model, like a cross section.

In summary, this approach is a game changer for CAE analysts. It eliminates the tedious tasks of post-processing and report generation, saving them time and effort. No more dealing with countless static slides and constant re-editing. Instead, they can rely on interactive 3D web visualization dashboards to effectively communicate insights to other stakeholders. And when combining this simulation data analytics technology within a SPDM system like VOLTA, organizations can also expect to speed up their simulation-driven design processes. Real-time collaboration becomes a reality with the ability to store, manage, and share simulation results on 3D CAD/CAE dashboards across business, design and simulation departments.

I joined Tech Soft 3D in 2020, following the acquisition of Ceetron AS where I had worked for 5 years. My background includes a mechanical engineering M. Sc (UCL, Louvain-La-Neuve, Belgium) and a material science Ph.D. (Ecole des Mines de Paris, France). I spent most of my 20+ year career in various technical positions ranging from solver developer to senior engineering manager. From 2019 onwards, I took up the challenge of taking my technical knowledge for a different ride to help get our products on the market. I am currently happily operating as Product Manager for CAE toolkits at Tech Soft 3D.

I joined Tech Soft 3D in 2020, following the acquisition of Ceetron AS where I had worked for 5 years. My background includes a mechanical engineering M. Sc (UCL, Louvain-La-Neuve, Belgium) and a material science Ph.D. (Ecole des Mines de Paris, France). I spent most of my 20+ year career in various technical positions ranging from solver developer to senior engineering manager. From 2019 onwards, I took up the challenge of taking my technical knowledge for a different ride to help get our products on the market. I am currently happily operating as Product Manager for CAE toolkits at Tech Soft 3D.

Overcome silos and make the best of simulation-driven product development.

Enabling the digital thread with VOLTA SPDM

Overcome silos and make the best of simulation-driven product development.

Enabling the digital thread with VOLTA SPDM

Overcome silos and make the best of simulation-driven product development.