How AISIN Corporation achieved significant cost savings for its electric powertrain units with design optimization

Written by Alessandro Viola and Manabu Kawaji

1 February 2022 · 5 min read

We met Manabu Kawaji from the Component Development Group at AISIN Corporation. He shares his experience in using our modeFRONTIER design optimization software to perfect electric powertrain components.

ESTECO: First of all, could you tell us a bit more about your company and its electrification initiative?

Manabu Kawaji: At AISIN Corporation, we design, develop, manufacture, and sell nearly all components that comprise a vehicle. Currently, we are accelerating our shift to electrification to improve fuel efficiency and reduce materials that place a burden on the environment by promoting the development of electric drive units, heat management systems, and electronically controlled brake systems. In particular, the powertrain division to which I belong develops a wide range of products including the eAxle, thermal management systems among others, that are essential in electrification vehicles and expand the sales ratio of electrification products to reduce CO2 emissions and promote fuel efficiency.

ESTECO: Why is simulation important for your product development?

Manabu Kawaji: Our company is committed to reducing product development time. The classic procedure where drawings are created first, prototypes next, and then finally products, is not feasible anymore. This is why we take advantage of simulation to speed up the engineering process and virtually prove a design rationale in order to deliver high-quality products to customers within a short period of time. Since the demand for electrified vehicles is rising, we need to use simulation technologies such as electromagnetic analysis, thermal design, and optimization to design electric powertrain units. Our customers usually provide us with requirement specifications to be used as a product overview, although it happens that we have to modify these specifications. This is the case where ESTECO’s modeFRONTIER design optimization software becomes crucial for us in order to be able to present the optimal motor design to the customer based on the modified specifications.

ESTECO: Could you explain why you chose modeFRONTIER software to perform design optimization?

Manabu Kawaji: We are aware of design optimization techniques as one of the best approaches to develop better products. The ability to perform design exploration and optimization studies and turn data into valuable insights to decide why a particular design is better than others was one of the key points to convince our senior management about the importance of optimization technology. In fact, modeFRONTIER became our standard optimization tool for motor design. The software is equipped with many features that facilitate its application to a design process: from an automated workflow that makes it possible to integrate any engineering solvers to advanced post-processing analysis tools that help us to present design rationale, and the capabilities to distribute the computational workload of large-scale optimization runs through grid computing. However, simulation is not easy to manage especially when you need a lot of simulation tools to perform various engineering analyses. They require you to buy many software licenses, and it is not always easy to prove the effective use of the software and determine the return on investment. In this scenario, modeFRONTIER simulation process integration and automation capabilities help us to maximize our investment in engineering solvers by integrating third-party tools such as GT-SUITE, Simcenter Flotherm, JMAG-Designer, MATLAB with the aim of performing multidisciplinary design optimization studies.

ESTECO: You said that you coupled modeFRONTIER with the JMAG software solution. Could you tell us a bit more about the benefit of this approach when performing electromagnetic field analysis?

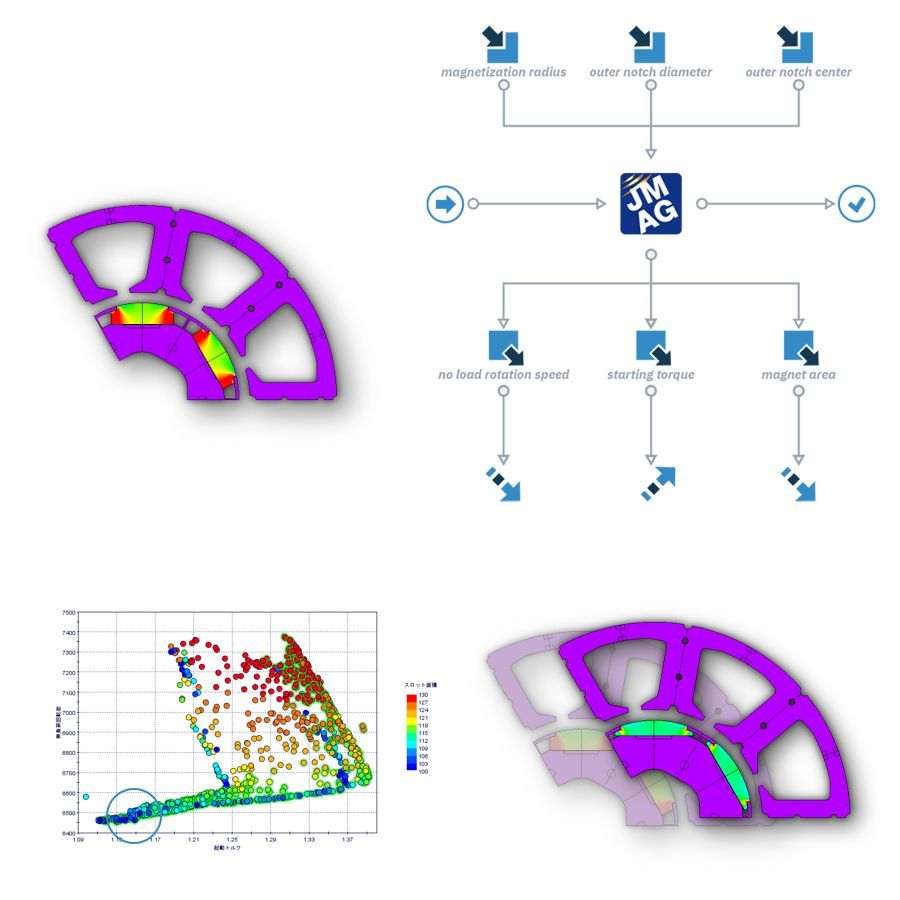

Manabu Kawaji: The electromagnetic field analysis is required to visualize the invisible physical phenomena of electricity and magnetic field and to clarify the design basis of electrified products such as motors. To do that we chose JMAG-Designer which is the most popular software solution for electromagnetic field analysis in Japan. Although, there are a number of motor optimization problems that need to be addressed and this is where modeFRONTIER comes into play. For example, we started with a 2D electromagnetic analysis of a magnet rotor performed by JMAG- Designer which shows the amount of magnetic flux interlinkage in the permanent magnet. Then, we integrated the JMAG simulation model into the modeFRONTIER workflow to perform multiobjective design optimization. The aim was to explore the inner/outer rotor shape and magnet shape that satisfy no-load rotation speed minimization, starting torque maximization, and permanent magnet minimization keeping or even increasing the magnetic flux interlinkage. Thanks to modeFRONTIER post-processing charts, we could visualize all the optimal designs on the Pareto front. And, then chose the ones with the lowest permanent magnet area and reduced no-load RPM which met our key requirements for production. In the end, this optimization methodology allows us to achieve significant cost savings for our electric powertrain units production.

The methodology of combining JMAG-Designer with modeFRONTIER to optimize the permanent magnet rotor for electric motors.

ESTECO: Do you have any future plans for simulation? Which is the impact of Machine Learning (ML) in your simulation design process?

Manabu Kawaji: We are actively investing resources to develop better products using a model-based development process that does not require physical prototypes anymore. Still, we have to figure out how to apply this methodology for thermal-related problems when designing and developing motors. On the other side, AISIN is very interested in applying Machine Learning (ML) based surrogate models to support the exploration of possible good solutions. There are various approaches such as creating surrogate models by integrating JMAG-Designer and modeFRONTIER and using Response Surface Models (RSMs) of modeFRONTIER at least for the initial investigation phases. Indeed, we are working to reduce the simulation costs (hardware and software) by employing these methods. RSMs accuracy is very important to obtain adequate results. We are in the early stages of usage and now we are investigating how to improve the accuracy of the surrogate models based on our simulation data.

Webinar on Demand