ESTECO’s future vision for industry 4.0, digital engineering technologies and product management

Written by Carlo Poloni and Uyiosa Abusomwan

29 June 2023

Dr. Uyiosa Abusomwan, lecturer for Rice University's Master of Engineering Management & Leadership (MEML) program, interviewed Carlo Poloni, president of ESTECO, to get his perspective on the future of Industry 4.0, digital engineering technologies and product development.

Products are Complex System-of-Systems

Abusomwan: With more organizations focusing on products to drive growth, product management has a bright future. What do you see as the future of engineering products from the lens of Industry 4.0?

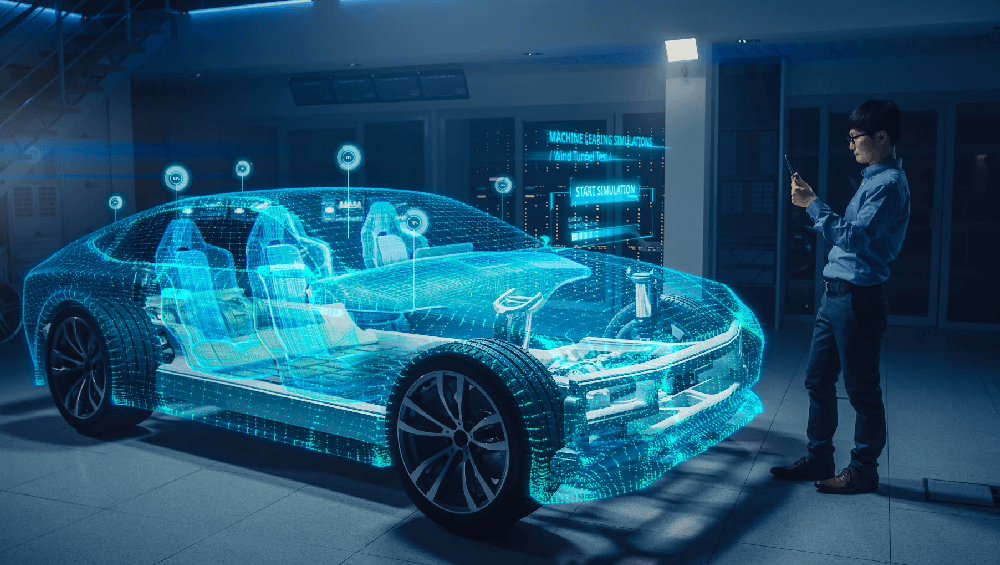

Poloni: As organizations shift their focus towards product-led growth, products are getting more complicated. One of the complexities that arises is the development of multiple unique functionalities within the same product. Let’s take modern cars as an example. They have become much more than just a mode of transportation. With the rise of technology, cars have transformed into entertainment hubs with cutting-edge audio and video integrations. Basically, the complexity and interaction between different engineering disciplines is becoming a major issue. At the end of the day, no one will have the full knowledge to master everything. In the future, good products will require a deep collaboration between different perspectives and competencies, in which no one will really prevail. And, decisions are taken in order to answer the best compromise between the different purposes for which global products are designed.

Expectations of Product Performance and Quality

Abusomwan: To address this complexity, what are the expectations on product performance, product reliability, product agility and product intelligence?

Poloni: Quality is an expectation. This means a nice experience when you use a product and it performs as you expect. For example, the car must be silent, easy to drive, energy efficient and maybe autonomous in the long term. Efficiency in any component is something that needs to be taken into account as much as possible in the early stages but also during the lifetime of a product. I expect that we are going to develop the physical and digital product at the same time. This means maintaining the digital product having the physical one on the side to continuously update the information. The goal is to be able to produce something better in the future or just keep it functional.

Abusomwan: The quality of the product needs to be outstanding in every discipline. How do we ensure that when we create products they come out with a high-level of quality?

Poloni: You need tools to quantify the quality. The perceived quality must be converted into quantitative performance indicators. In the case of noise, for example, there is probably a threshold that needs to be measured and it can be managed through simulation. The quality of an engine is its ability to the power requests, and this can also be simulated. To do things properly, simulation has to be of high quality and it is necessarily produced by someone who is an expert in that specific field. With this regard, it is still difficult to balance the need to get information quickly with the need to make accurate decisions. To address this, the most sophisticated simulations should be also available to someone that for his business can’t be an expert of a specific discipline but needs to assess the quality in quantitative terms to drive the decision-making process. The transfer of knowledge is one of the big challenges that we have to face in designing sophisticated products of the future.

Simulation Data Analytics and AI

Abusomwan: To get into the future of product development, what emerging technologies can help engineering leaders and organizations to develop products with the type of performance, quality and reliability?

Poloni: As always, there are two things that need to go in parallel, software tools and people. To reach future goals in product development, we need to collect data, interpret them and produce new results in terms of design processes. How to achieve this? We need to do accurate simulations using the available software tools as much as possible to produce data. The next step is to interpret these data with data analytics and AI-powered software tools. However, there is still an organizational issue. We need to change the company’s culture in simulation in order to be able to use this data inside the organizations and give feedback on it for the design of the product. A structured organizational process is absolutely important in order to reach this.

SPDM and CAE Democratization

Abusomwan: Organizational change is one of the key aspects in simulation. How do we enable people to make better decisions for engineering product development?

Poloni: We need to enable individuals to use the most sophisticated information even if they don’t know exactly how to build them. In our field, you hear the word democratization which means making simplified simulation of components and making it possible even for people that were not much trained. We should reinterpret the word democratization of simulation work. Making the most sophisticated simulations available to other people, not by simplifying the method but making a good interface. This means thinking about an organization that has expert people who are concentrated on building the right model and the boundaries between which the model is applicable. Once it is done, this part becomes a sort of black box which can be used by decision makers and anyone inside the company. This is different from what happened in the past, when engineers analyzed a design problem saying “this is broken because of this and this”. That expertise has to become available in the complete lifetime of the products. You should dedicate some people in developing sophisticated tools to simulate and build an interface on an appropriate Simulation Process and Data Management (SPDM) platform which allows the company to cut the product development time.

Business Process Management (BPM) in Simulation

Abusomwan: As a leader in providing software solutions for numerical optimization and simulation data management for over two decades, can you share some insights on how you are making these technologies available and to enable people to create the next generation of technical products?

Poloni: At ESTECO, we do two things. From one side, whatever we develop has to be compatible and usable by other stakeholders. The openness of the system is crucial because you always have to interface with a software solution from someone else. And then the availability of information in time and space from many devices is an important aspect for us, everything will have to live on the network. We will need to share our data with the development team that may live in a different country or even in a different continent. In addition, we need to add people in the process. There are still tasks which are related to individual activities. For example, the most trivial thing like certifying if the simulation results are good or not. This needs the expertise of someone going there and saying “yes the model can be used”. This activity requires a person in the process which means that we need to manage processes which are not fully automated. And, this is another direction where our company ESTECO is working for. We embraced Business Process Modeling and Notation (BPMN) 2.0 standard in order to model engineering design processes in a standard way. Doing it in a standard way, so other software tools can get involved, so there won’t be silos, and using the web to accomplish this process on a network.

Key technologies for developing products of the future

Abusomwan: ESTECO is a rapidly growing company today enabling organizations, product teams and project managers to create high-quality products by doing that early in the design development cycle. Can you highlight the key technologies that you focus on and potentially how they would help engineering leaders to develop the next generation of their product?

Poloni: We have well established technologies for modeling simulation workflows, applying design optimization techniques and performing advanced data analysis and decision intelligence. Further, we added methodologies for taking decisions in a formalized manner, sharing these information across continents and across different parts of the organizations by preserving the intellectual property rights (IPR). When doing a sophisticated product you will probably need to have partners that provide you components, you will not want to share the performance of the component, but on the other hand the two partners need to preserve the development done over the year. Creating an ecosystem where models can be exchanged in terms of responses, while preserving the IPR, is something that we are currently working on to enable engineering teams and external partners to contribute with their model to build the complete product.

Uyiosa Abusomwan is a Professor of Practice at the Rice Center for Engineering Leadership, Rice University. In this role, he designed and instructs a graduate course on product management in industry 4.0 within the Master of Engineering Management & Leadership Program. Additionally, Uyiosa serves as the senior global technology manager of digital engineering at Eaton Corporation. In this position, he leads corporate strategies to facilitate the integration of emerging technologies, enhanced engineering efficiency, and streamlined product lifecycle management. His combined experiences in academia and industry positions him as an advocate and passionate leader in product development, product lifecycle management, and digital engineering.

Uyiosa Abusomwan is a Professor of Practice at the Rice Center for Engineering Leadership, Rice University. In this role, he designed and instructs a graduate course on product management in industry 4.0 within the Master of Engineering Management & Leadership Program. Additionally, Uyiosa serves as the senior global technology manager of digital engineering at Eaton Corporation. In this position, he leads corporate strategies to facilitate the integration of emerging technologies, enhanced engineering efficiency, and streamlined product lifecycle management. His combined experiences in academia and industry positions him as an advocate and passionate leader in product development, product lifecycle management, and digital engineering.

Overcome silos and make the best of simulation-driven product development.

Enabling the digital thread with VOLTA SPDM

Overcome silos and make the best of simulation-driven product development.

Enabling the digital thread with VOLTA SPDM

Overcome silos and make the best of simulation-driven product development.