CIMdata’s point of view: ESTECO provides value through simulation and design optimization in the digital thread

Written by Alessandro Viola

29 January 2025 · 5 min read

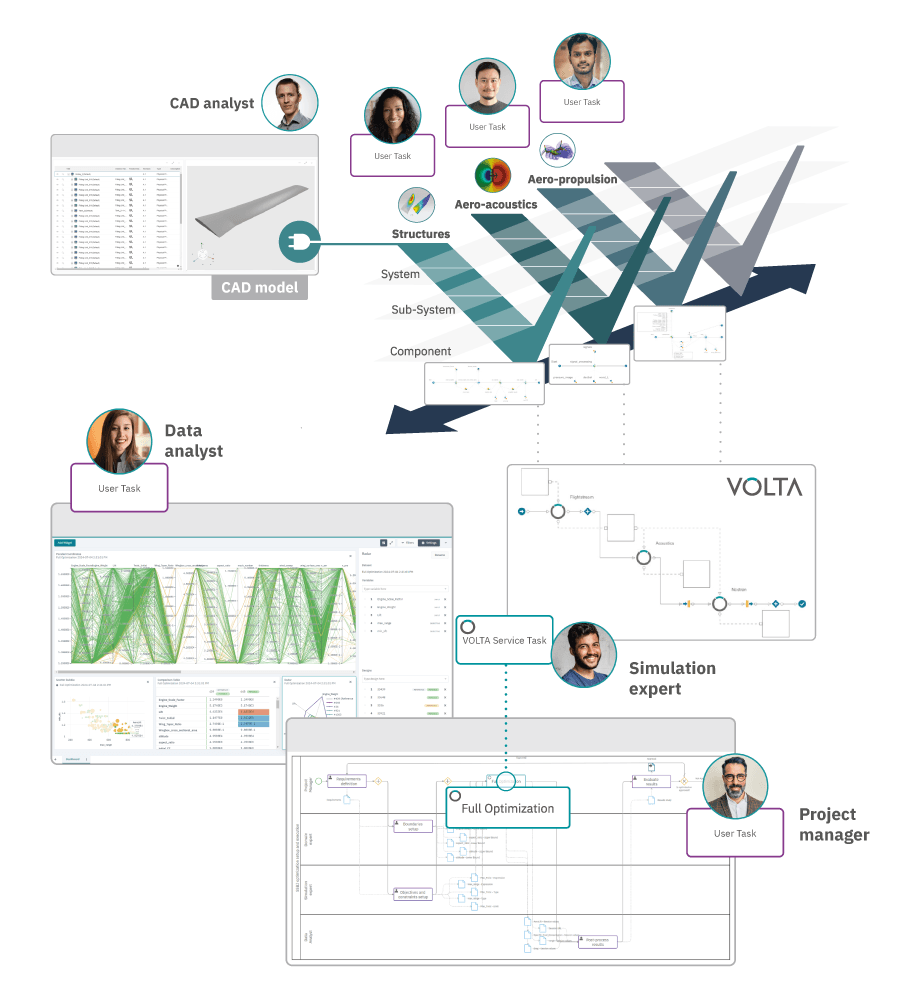

This commentary by CIMdata, the leading independent global strategic management consulting and research authority specializing in product lifecycle management (PLM) and digital transformation, explains how ESTECO VOLTA's simulation process and data management (SPDM) platform, combined with modeFRONTIER technology for multidisciplinary design analysis and optimization (MDAO), offers a powerful suite of solutions for simulation-driven product development. The commentary also highlights how these tools connect with other enterprise level PLM-driven processes to create a digital thread.

CIMdata recognizes the value of integrating MDAO and SPDM with external systems like PLM

1. Simulation artifacts should not be siloed in separate systems

The use of simulations across the product lifecycle has grown over the years. However, simulation artifacts have largely remained siloed in separate systems across design, testing, and validation workflows. Most organizations also lack proper data organization. There is a need to establish traceability for both the data and process information used in simulations, as well as for the simulation results. By connecting simulations to the digital thread, organizations can create a unified environment where design, analysis, and decision-making processes are seamlessly integrated into the broader product development lifecycle.

2. A separate SPDM with usage-based integrations with PLM solutions may be a reasonable solution

While PLM solutions are well established across the industry for managing design, manufacturing, and supply chain information, simulation data has largely been excluded from PLM systems. Simulation data requires a dedicated data architecture specifically for verification and validation (V&V) activities. SPDM provides a centralized environment that manages, organizes, and integrates simulation and test data, analysis models, reports, materials data, and orchestrates best practice workflows using multi-vendor design and analysis tools.

3. Automate simulation and design optimization workflows into the digital thread with the ESTECO VOLTA digital engineering platform

An emerging industry need is the ability to automate design optimization earlier in the product development lifecycle. As product complexity and the demand for shorter development cycles grow , traditional trial-and-error approaches to design are no longer sufficient. Automated workflows for simulation and design optimization enable engineers to explore a broader design space, identify optimal solutions faster, and make data-driven decisions, while minimizing manual intervention.

The use of ESTECO VOLTA along with its External data sources connector and modeFRONTIER offers a promising solution for early adopters seeking to manage the complex data and workflows associated with simulation-driven product development.

The ESTECO VOLTA digital engineering platform facilitates the integration of simulation models and data from PLM systems into simulation workflows, allowing users to run MDAO studies and manage results within VOLTA. This enables rapid evaluation of design candidates and optimal configurations, while ensuring traceability and fostering collaboration across teams.

Realize the value of simulation and MDAO in the enterprise digital thread.

Enriching PLM’s landscape with multi-physics simulation processes and data

Realize the value of simulation and MDAO in the enterprise digital thread.

Enriching PLM’s landscape with multi-physics simulation processes and data

Realize the value of simulation and MDAO in the enterprise digital thread.