ESTECO collaborates with leading automotive and aerospace companies in India to accelerate their simulation-driven design processes

Written by Anirudha Joshi

27 September 2023 · 5 min read

On August 23, 2023, the 2nd edition of our ESTECO Users’ Meeting India was held in Bangalore. Over a hundred engineering enthusiasts met in the so-called “Silicon Valley of India” to gain insights on how leading OEMs such as Cummins, Aeronautical Development Agency (ADA), Centre for Airborne Systems (CABS), Forvia Faurecia, Mahindra & Mahindra, and Tata Motors to name a few have implemented ESTECO’s software solutions to improve design performance, speed up engineering design processes and achieve their business goals in the age of digital transformation.

In today's rapidly evolving industry, where customer preferences, performance demands, and regulatory compliance play a crucial role, product life cycles are indeed shrinking. This puts immense pressure on simulation and product development teams to deliver high-quality products within shorter timeframes. To cope with these challenges, companies are increasingly turning to collaboration, AI/ML (Artificial Intelligence/Machine Learning), and productivity enhancements to maximize their return on investment in engineering simulation technology.

In this context, we presented the recent developments of our VOLTA and modeFRONTIER software solutions to demonstrate our commitment to providing our Indian users with state-of-the-art digital engineering technologies to foster innovation in engineering simulation and analysis. By providing VOLTA digital engineering platform with the capability to scale multidisciplinary design optimization (MDO) across the enterprise, we focus on achieving democratization, simulation governance, and digital thread integration in the engineering design process. With Python becoming a popular programming language for engineering applications and numerical computations, we have developed a Python ecosystem within modeFRONTIER to take advantage of its capabilities. It allows you to create custom simulation workflows as well as perform ML-based data analysis and predictive modeling.

Further, the use of ML can make an impact to accelerate computational fluid dynamics (CFD) simulations while maintaining accuracy. Haysam Telib, Co-founder and CTO at Optimad - our partner company, presented an innovative approach to leverage CFD data and democratize its usage with reduced order modeling (ROM) techniques. By combining Optimad romBOX - a toolbox from ROM and ML with VOLTA platform, you can enable non-simulation experts to perform accurate aerodynamic performance evaluations in a fraction of time.

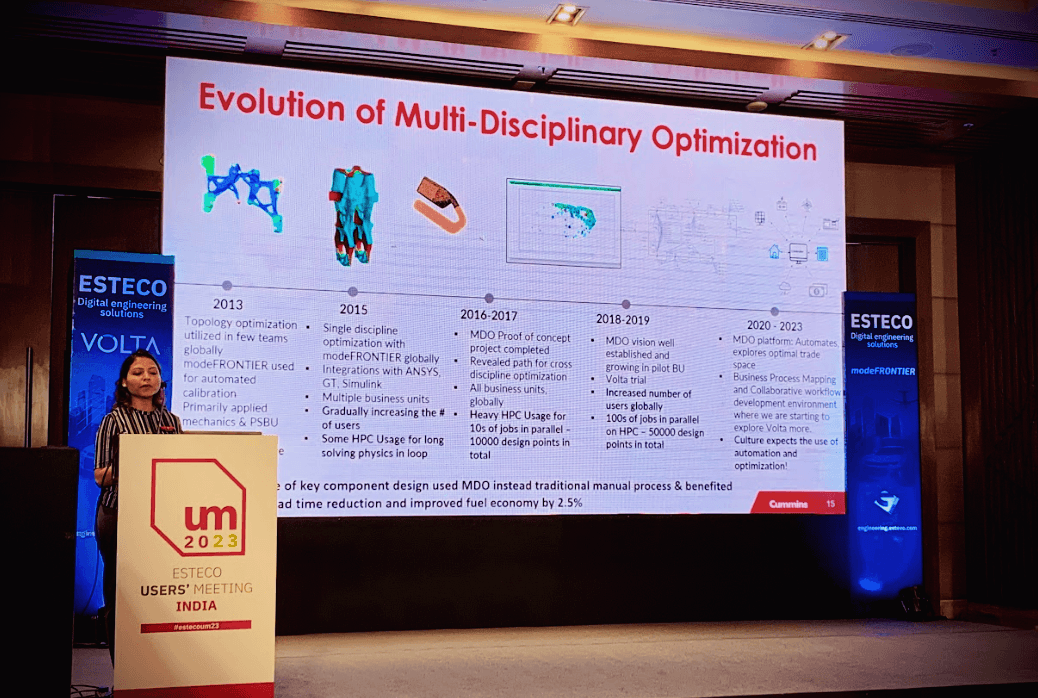

VOLTA digital engineering platform helps Cummins to democratize their simulation based product development

At Cummins, process automation is a crucial part of simulation based product development as it facilitates data driven and closed loop decision-making. They currently focus on integrating VOLTA web-based multidisciplinary design optimization (MDO) framework into their simulation culture as a key accelerator to democratize simulation models and data. Tejasvini Nale, Technical Manager at Cummins India, emphasized how using MDO instead of traditional manual process they achieved one month lead time reduction and improved fuel economy by 2.5%.

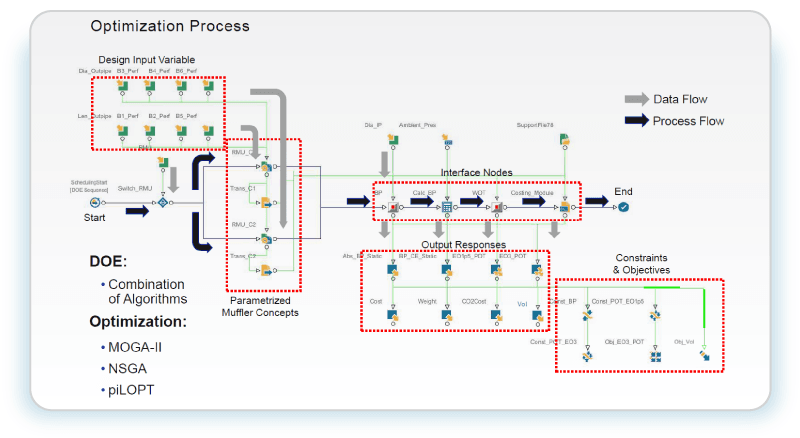

Optimization approach for exhaust system development at Forvia Faurecia

Sushanth Shettigar, Technical Lead Acoustics - Senior Specialist at Forvia Faurecia Clean Mobility, demonstrated how they used modeFRONTIER to address the complexity of their multidisciplinary design project for exhaust system development. As a result of setting up a simulation workflow and defining an optimization strategy in modeFRONTIER, they were able to achieve a design of an exhaust system that had a lower cost of materials (BoM), a lower CO2 emissions, and a reduced mid silencer volume while meeting acoustics and mass reduction objectives.

modeFRONTIER's workflow set-up for exhaust system design optimization

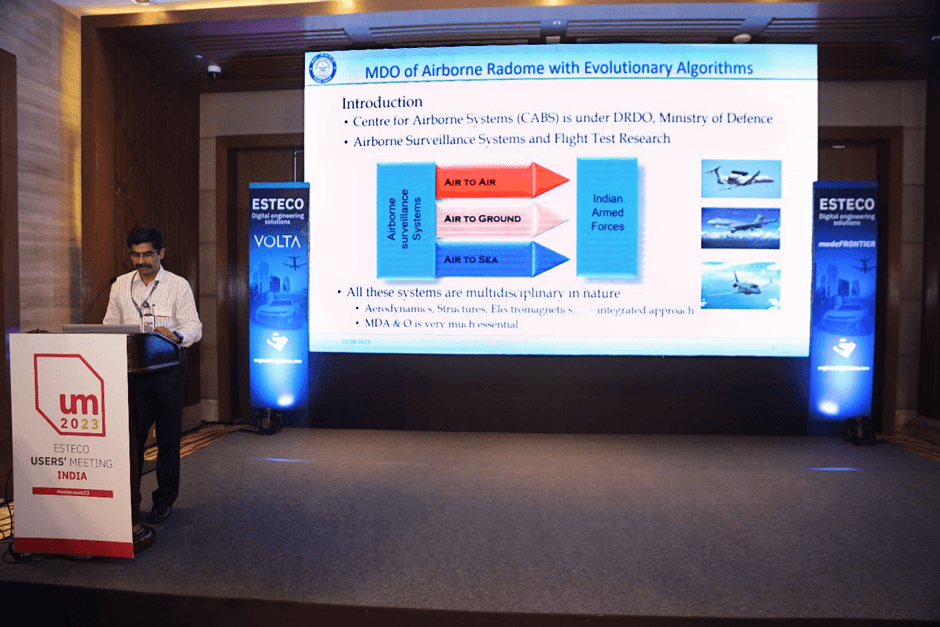

Centre for Air Borne Systems optimizes AWACS Radome with modeFRONTIER

Radome design is a multi-disciplinary problem which involves electromagnetic, structural and aerodynamics disciplines. Dr M R Shankar,Head of Aircraft Division at Centre for Air Borne Systems (CABS) – a leading Defence Research and Development Organization (DRDO) Lab, presented a multidisciplinary design optimization (MDO) methodology to design Radome while managing the conflicting objectives of lower drag, lower electromagnetic loss and higher structural strength at lowest weight in single workflow. The methodology included the use of sensitivity analysis and the results were demonstrated using 3D Pareto Charts in modeFRONTIER.

In summary, the ESTECO Users’ Meeting India 2023 was a remarkable gathering that provided a glimpse into the future of engineering simulation. In an ever-evolving landscape, the demand for state-of-the-art digital engineering tools and techniques has become increasingly evident. The event served as a testament to the dedication of ESTECO, its partners (Altem Technologies, Axiomatic iTech, Modelon India), and attendees to push the boundaries of what is achievable in the world of engineering and simulation. We look forward to continuing our journey together at the next ESTECO Users' Meeting India in 2025. Meanwhile, if you want to get access to the proceedings and learn more about other customers’ presentations like Mahindra & Mahindra, Aeronautical Development Agency (ADA) and Tata Motors, please contact us at marketing@esteco.com

Step-by-step guide into modeFRONTIER - the intuitive vendor agnostic software for process automation and design optimization.

Expedite design process with cutting-edge optimization technology

Step-by-step guide into modeFRONTIER - the intuitive vendor agnostic software for process automation and design optimization.

Expedite design process with cutting-edge optimization technology

Step-by-step guide into modeFRONTIER - the intuitive vendor agnostic software for process automation and design optimization.